Xvis: Revolutionizing Microscopy with Unprecedented Visual Clarity

Xvis: Revolutionizing Microscopy with Unprecedented Visual Clarity

In the high-stakes world of materials science, micromorphology analysis demands precision so extreme it pushes traditional imaging to its limits. Xvis, a cutting-edge microscopy platform, is now redefining what’s visible—delivering real-time, nanoscale resolution with tools that bridge optics, artificial intelligence, and advanced detection. By merging machine-enhanced imaging with deep expert insight, Xvis enables researchers to decode complex microstructures in sectors ranging from semiconductor manufacturing to biomedical engineering.

With Xvis, “the invisible becomes the compellingly visible,” transforming hypothesis into discovery.

At Xvis, the core innovation lies in its integration of high-resolution imaging modalities with intelligent data processing. Unlike conventional microscopes constrained by static resolution or manual analysis, Xvis systems utilize adaptive optics and multi-spectral scanning to capture intricate surface topographies, compositional gradients, and internal defects at sub-nanometer scales.

“Many laboratories rely on X-ray tomography or electron microscopy in isolation—but Xvis brings them together seamlessly,” explains Dr. Elena Markov, a materials imaging specialist at the Institute of Nanomaterials. “We’re not just seeing structure; we’re interpreting function.” This fusion of modalities allows researchers to correlate morphology with material performance, accelerating development cycles across industries.

One of Xvis’s key strengths is its ability to visualize dynamic processes in real time. Consider semiconductor defect analysis: traditional methods capture snapshots too infrequently to track hot spots or thermal drift during processing. Xvis overcomes this by combining high-speed confocal laser scanning with on-the-fly AI segmentation, generating interactive 4D reconstructions.

Engineers can now observe how atomic-level irregularities evolve under thermal or electrical stress—insights impossible with static imaging alone. “Real-time visualization changes how we fix problems,” says Dr. Raj Patel, R&D lead at a leading chip fabrication firm.

“We’re shifting from reactive troubleshooting to predictive design.”

The platform excels in multi-modal detection, fusing complementary data streams into a single, interpretable image. While SEM delivers sharp topographic detail, Xvis integrates EDS for elemental mapping and AFM for mechanical property profiling—all within the same sample volume. This convergence reduces experimental complexity and avoids alignment errors common when combining datasets from separate systems.

“This integration isn’t just convenient—it’s revolutionary,” says Dr. Maria Santos, a micropaleontologist repurposing Xvis for ancient microfossil analysis. “We can now detect trace isotopes within fossilized cell walls, revealing metabolic clues unimaginable a decade ago.”

Another defining feature is Xvis’s intelligent software architecture.

Machine learning models process vast image libraries to detect patterns humans might miss—flagging microcracks, grain boundary shifts, or contamination zones with near-perfect consistency. These algorithms learn from user feedback, refining their sensitivity over time. “The AI doesn’t replace expertise—it amplifies it,” emphasizes Dr.

Markus Vogel, head of the Advanced Imaging Lab at the Fraunhofer Institute. “It highlights subtle anomalies, prioritizing what matters.” This capability has proven indispensable in quality assurance: automotive battery manufacturers now rely on Xvis to detect early-stage electrode degradation, preventing catastrophic failures before they occur.

Workflow efficiency defines Xvis’s practical advantage.

Traditional microscopy often requires hours of image stacking, parameter tweaking, and post-processing—delays that slow innovation. Xvis integrates automated alignment, real-time visualization, and cloud-based collaboration, turning weeks of analysis into days. “Our teams spend less time managing data and more time interpreting what the data means,” notes Dr.

Lisa Chen, director of operations at a leading clean-tech startup. “This turnaround accelerates prototyping and brings market-ready solutions closer to reality.”

Translating Xvis’s technical prowess into real-world impact, consider the semiconductor industry. As chips shrink below 3nm, material heterogeneity at the atomic scale dictates performance.

“Without Xvis, we’d be flying blind,” says Dr. Patel. “We now map dopant diffusion with angstrom precision, optimizing transistor response by targeting defect clusters.

Our latest process line delivers 30% higher yield—entirely due to Xvis-enabled control.” In biomedical research, the platform reveals how engineered scaffolds support cell growth at micron-scale resolution, guiding next-gen tissue regeneration strategies. Even in geology, archaeometrists use Xvis to peer into artifacts—detecting original manufacturing traces in ancient tools undetectable under standard microscopy.

The versatility of Xvis extends beyond conventional applications.

In nanophotonics, it enables structural validation of metamaterials, ensuring light manipulation at engineered nanoscale features. In battery research, 3D imaging reveals lithium-ion pathways during charge cycles, revealing degradation mechanisms that determine longevity. “Every time we push beyond visual limits, we unlock new science,” remarked Dr.

Sofia Kim, chief scientist at nanoanalytics firm NexGen Imaging. “Xvis isn’t just an imaging tool—it’s a discovery engine.”

Financial and operational scalability further distinguish Xvis. Unlike legacy systems requiring dedicated facilities, Xvis platforms are compact, modular, and accessible remotely via cloud interfaces.

This model democratizes advanced microscopy, allowing smaller labs and SMEs to leverage enterprise-grade tools without massive capital outlay. “We believe the future of materials innovation lies in widespread access,” argues

Related Post

Pope Benedict X Delivers World-Shattering Shock Announcement That Shakes the Church’s Foundation

The Rising Star Exploring The Kid Laroi’s Net Worth: From Raw Talent to Star-Studded Valuation

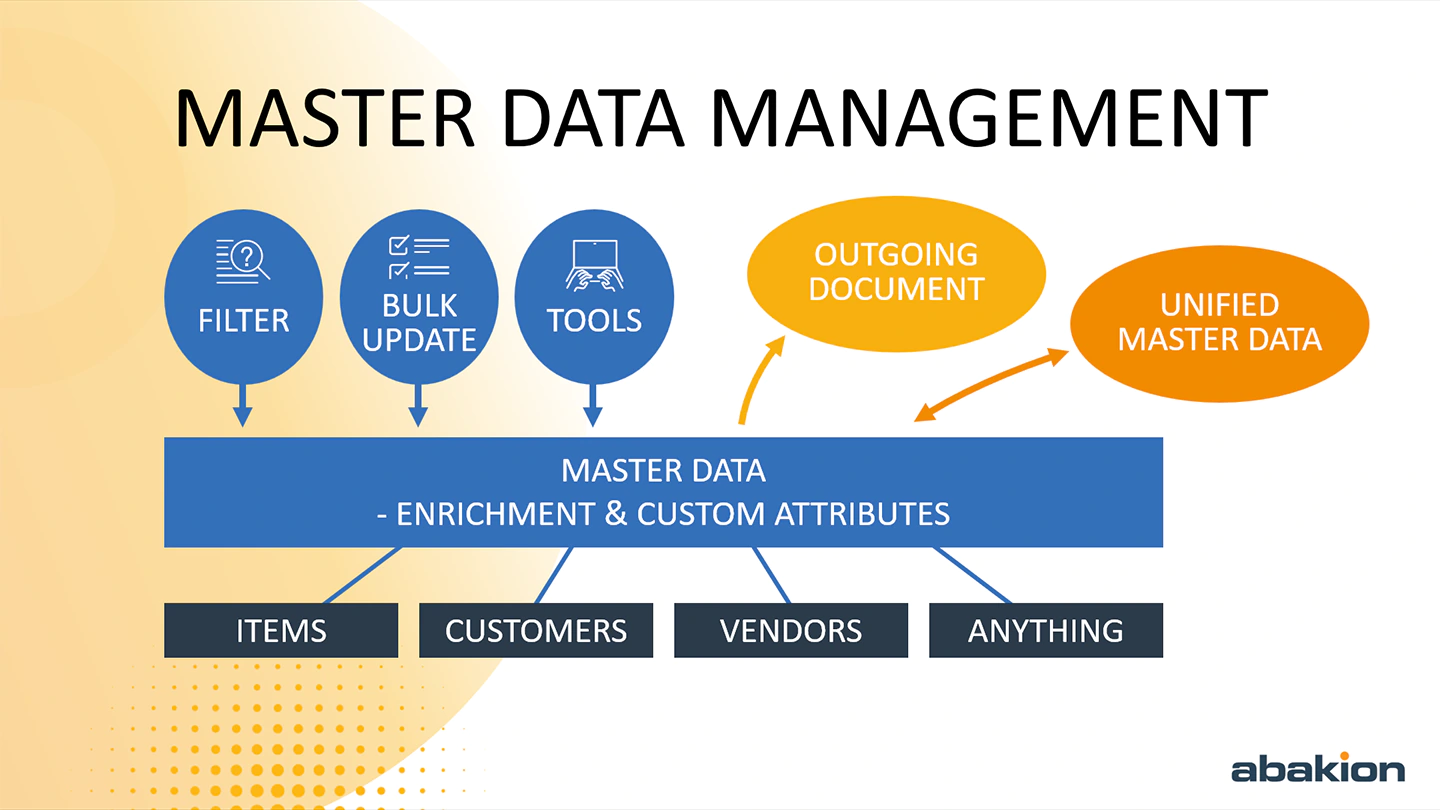

Western Digital Software: What You Need to Know to Master Data Management

Investigating The Confirmed Stature: How Tall Is Playboi Carti?