What Is An Orifice? The Hidden Gateway Shaping Flow in Science and Engineering

What Is An Orifice? The Hidden Gateway Shaping Flow in Science and Engineering

From the microscopic flow of blood through capillaries to the massive pressure-controlled valves in industrial pipelines, the term “orifice” plays a foundational role in understanding fluid dynamics across nature and technology. An orifice is not merely a hole—it is a precisely engineered understanding of fluid movement between regulated spaces, governed by physics principles that dictate flow rate, pressure, and resistance. Whether in medical devices, mechanical systems, or geological formations, the orifice serves as a critical control point, measuring or regulating the transfer of liquids and gases with remarkable precision.

Its definition, function, and real-world applications reveal a concept far more dynamic and impactful than its simple appearance suggests.

The Core Definition: Understanding What Constitutes an Orifice

At its most fundamental level, an orifice is an opening—often circular or elliptical—through which fluids (liquids or gases) pass from one region to another under pressure differences. In scientific terms, it is a discontinuity in a containing boundary where fluid velocity increases as it moves into a lower-pressure zone. This phenomenon is anchored in fluid mechanics: when a fluid encounters an constricted aperture, Bernoulli’s principle and the continuity equation illustrate how velocity rises while pressure drops.Historically explored by early physicists like Daniel Bernoulli, the orifice remains a key focus in applied fluid dynamics. An orifice may vary dramatically in size—from micrometer-scale holes in diagnostic sensors to meter-wide valves in dam spillways—and in purpose, from restricting flow to precisely measuring it. Key characteristics include: - **Controlled geometry**: Shape, diameter, and edge design directly influence flow characteristics.

- **Pressure-driven flow**: Movement is governed by pressure differentials across the opening, not passive diffusion. - **Rate-determining factor**: Through equations like Torricelli’s law, flow velocity correlates directly to the orifice’s ratio (exit area to container cross-sectional area) and the pressure difference. “This small aperture controls immense energy transfer,” notes Dr.

Elena Martinez, a fluid dynamics specialist at MIT. “The orifice is not just a passage—it’s a controlled interface where physics meets practical impact.”

Types of Orifices: Precision in Design Across Applications

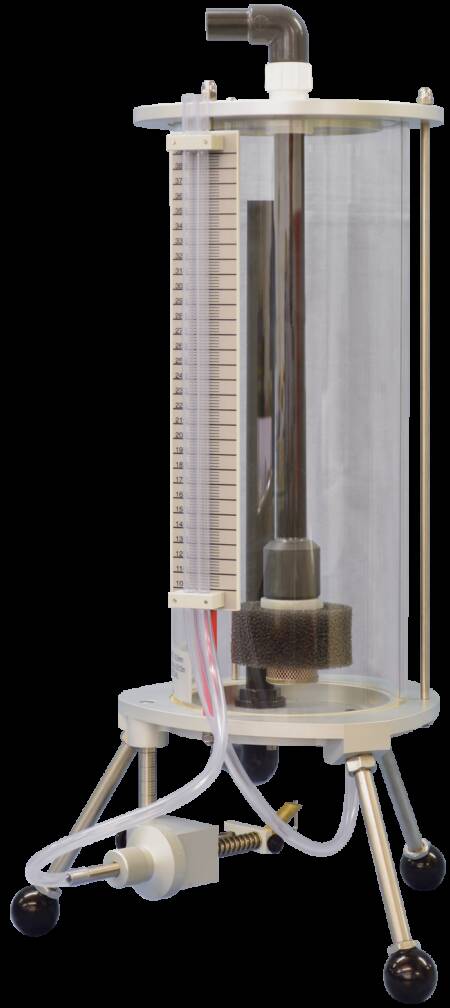

Not all orifices are created equal—each type serves a specialized role shaped by its purpose and environment. Understanding the distinctions among common orifice designs clarifies their functional diversity.Fixed Orifices: The Basics of Fluid Measurement

Fixed orifices consist of rigid, predetermined holes—often cast or drilled—used primarily for flow measurement. Their standardized dimensions allow consistent regulation, making them indispensable in industries like water treatment, petroleum refining, and chemical processing. For example, a simple ring-shaped orifice in a pipe’s side wall directs flow through a known cross-sectional area, enabling engineers to calculate volumetric throughput using pressure differentials.Their simplicity ensures reliability, low maintenance, and repeatability—critical in systems where accuracy is nonnegotiable.

Variable Orifices: Adaptive Control in Dynamic Systems

In contrast, variable orifices adjust in real time, responding to shifting pressure or flow demands. Common in hydraulic systems, these can be mechanical or smart-enabled, altering the effective opening size.This adaptability maintains optimal performance amid varying loads, reducing energy waste and wear. An early example lies in aircraft landing gear systems, where dynamic orifices regulate hydraulic fluid flow during takeoff and touchdown, ensuring stability. Today, microelectromechanical systems (MEMS) create ultra-precise, electronically controlled variable orifices, enabling responsive, automated fluid regulation in medical devices and industrial robotics.

Geometric Variants: Circular, Elliptical, and Beyond

Beyond standard circular holes, orifices exist in shapes tailored to specific fluid behaviors. Elliptical orifices minimize flow turbulence in gas systems, while annular designs—ring-shaped with concentric edges—optimize flow uniformity in high-velocity applications. Each shape influences boundary effects, shear forces, and pressure recovery, directly affecting efficiency and system longevity.In fuel injection nozzles, precisely shaped orifices ensure atomized fuel spray, enhancing combustion performance and reducing emissions.

Applications: Orifices as Linchpins in Science and Engineering

The versatility of orifices makes them vital across disciplines, from life-saving medical tools to massive industrial infrastructure.Industrial Flow Regulation: Ensuring Efficiency in Pipelines

In petrochemical and water treatment plants, orifice plates install into pipelines to monitor and regulate flow rates with minimal disturbance.By measuring pressure differences across the orifice, operators adjust valve positions or restrictors to maintain optimal throughput, preventing surges that could damage equipment. These systems depend on precise mathematical models—like BC (orifice coefficient) equations—to convert pressure readings into flow rates, forming the backbone of automated process control.

Medical Devices: Critical Components in Patient Care

In life-critical devices like oxygen masks and infusion pumps, tiny orifices control gas or fluid delivery at precise rates.Fi/O (flow vs. orifice) relationships are engineered to ensure steady oxygen flow for respiratory therapy, while micro-orifices in drug delivery systems enable accurate medication dosing. For example, catheter-based orifice designs in dialysis machines precisely regulate dialysate flow, balancing patient safety with therapeutic effectiveness.

“In medicine, an orifice isn’t just a hole—it’s a lifeline governed by micrometer-scale precision,” highlights Dr. Rajiv Patel, biomedical engineer at Johns Hopkins.

Safeholding Infrastructure: Orifices in Dams, Siphons, and Natural Flow Control

Large-scale orifices play a pivotal role in civil engineering.Spillways in dams use massive structural orifices to manage floodwaters, their geometry engineered to safely dissipate energy and prevent catastrophic structural failure. Similarly, siphon systems channel water across valleys via controlled openings, maintaining consistent vertical flow. Even natural analogs emerge in cave systems, where narrow flow channels regulate underground water movement—guided by the same principles engineers apply in man-made conduits.

Environmental and Geological Flow Management

Orifices also feature in environmental monitoring. Soil moisture sensors embed small, secure orifices that regulate air-water exchange, enabling accurate readings of subsurface conditions important for agriculture and drought prediction. In

Related Post

Menards Pekin IL: Your Go-To Home Improvement Store for Every Project

Kelly Dodd Real Housewives Bio Wiki Age Husband Daughter House and Net Worth