VCC And GND In Breadboards: The Essential Electrical Heartbeat Every Beginner Must Master

VCC And GND In Breadboards: The Essential Electrical Heartbeat Every Beginner Must Master

In the world of electronics, where circuits form the foundation of innovation, understanding the building blocks of connectivity is fundamental. Nowhere is this more critical than in breadboard-based prototyping—where vacuum-clear clearances and wiring without soldering demand precision in every connection. At the core of this silent digital ballet are two essential power contacts: VCC (the high-voltage supply line) and GND (ground, the return path and common reference).

Mastering how VCC and GND are implemented, identified, and managed on breadboards is the cornerstone of reliable circuit design—especially for novice makers grounded in hands-on experimentation. Breadboards function as temporary breadboards—literally and functionally—allowing rapid assembly of circuits without permanent soldering. Yet, within this modular framework, the proper allocation of voltage (VCC) and ground (GND) remains a silent but vital discipline.

VCC supplies the necessary electrical energy to power semiconductors, while GND ensures circuit stability by providing a shared zero-voltage reference point. Misplacing or mismanaging these lines introduces noise, erratic behavior, and potential component failure—outcomes no beginner should encounter.

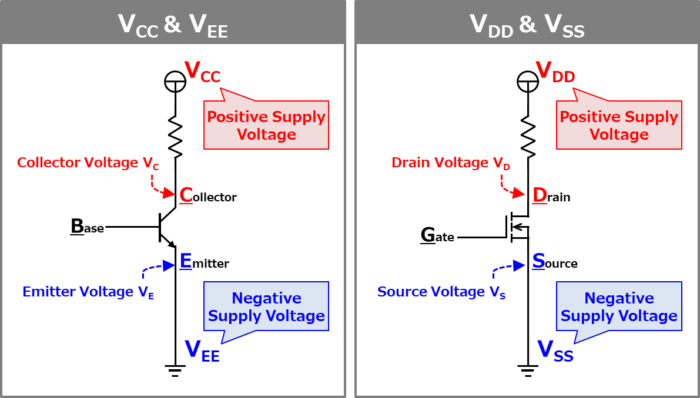

Understanding the roles of VCC and GND begins with recognizing their electrical definitions.

VCC, typically connected to a regulated power source like a battery pack or breadboard power rail, delivers the climbing voltage needed to energize active components such as microcontrollers, transistors, and logic gates. Without a stable VCC, circuits remain feeble, silent, or unpredictable. By contrast, GND serves as the circuit’s zero-voltage backbone—connecting all ground returns, shields, and reference points to prevent voltage fluctuations and ensure consistent operation across devices.

On a breadboard, GND is almost universally connected along one edge, often labeled with the symbol GND in schematics and physically linked via large concatenated bus bars.

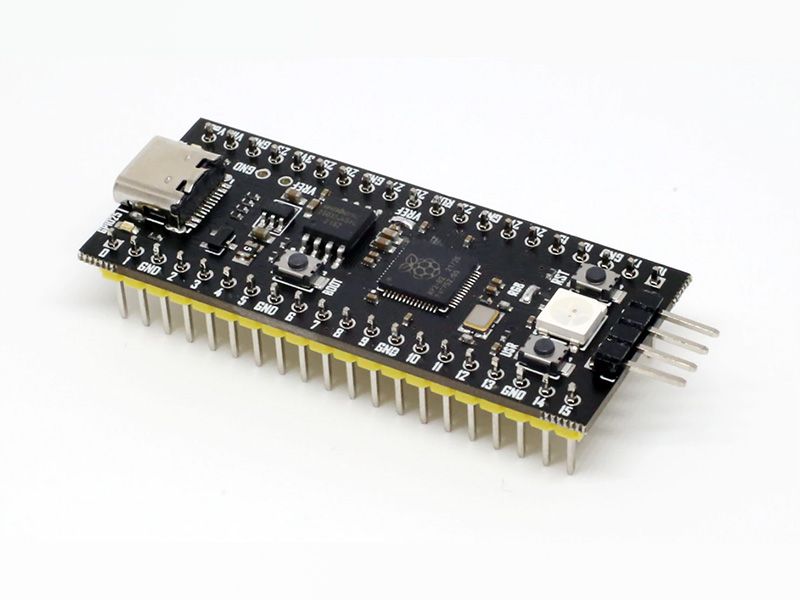

Its ubiquity reflects its role as the “common”。 VCC, now and then labeled with +5V, +3.3V, or even battery references, connects to specific input pins on integrated circuits or through jumper wires to external power supplies. The physical connection—usually a small dual-purpose or power pin—must be clean, secure, and properly insulated to avoid voltage drops or unintended current paths. Geometry and placement demand care.

VCC pins should coil close to power inputs from batteries or DC sources and extend slightly to minimize trace resistance. GND connections should blanket multiple input lines or form a single, wide bus bar to reduce impedance, a practice praised by experienced engineers as vital for preventing voltage bounce during transient current demands. “When designing a breadboard circuit,” notes electronics instructor Maria Lin, “failing to connect GND properly is akin to building a house without a foundation—everything may appear solid until a circuit’s current surges.”

Visual differentiation is key in avoiding shorts and confusion.

VCC pins—often colored red or labeled with voltage indicators—contrast clearly with GND’s typical black or copper-colored connections. Jumper wires, typically red (VCC) and black (GND), serve as standardized guides, though advanced builders may use breadboard-specific clips or breakaway headers for flexibility. But even with color coding, the loop of best practice remains: VCC connects first, then GND—connected directly and collectively—ensuring minimal loop area and reduced electromagnetic interference.

Many beginners overlook the importance of separating analog and digital grounds, risking ground loops and noise coupling into sensitive circuits. While breadboards often converge GND into a single reference, intentional isolation—using separate ground planes in larger projects—can dramatically enhance signal integrity. However, within a single breadboard environment, consolidating both VCC and GND on adjacent rows preserves signal path clarity and reduces parasitic resistance, especially when components switch states rapidly.

Real-world experimentation illustrates the necessity of correct polarity and continuity. A voltage source incorrectly angled at VCC can scorch sensitive logic inputs; a disabled GND connection even in low-power circuits may trigger false resets or erratic behavior. Testing with a multimeter—measuring voltage at VCC and continuity across GND pairs—provides immediate feedback, empowering makers to validate their setup before energizing entire designs.

The hierarchy of connections doesn’t stop at power and ground. Pinout precision—knowing which VCC and GND ends link to specific components—directly influences circuit function. Marco Rossi, a senior electronics lab supervisor, emphasizes: “VCC and GND are not just wires; they are the electrical anchors.

Misalignment or weak joints introduce resistance, voltage drops, and thermal stress—silent failures hiding beneath a green jumper.”

Breadboard safety and efficiency also hinge on proper multimeter usage. Confirming continuity between GND and circuit grounds prevents accidental backfeeding. Avoiding tight bends in jumper traces maintains low impedance.

Using pre-crouched mousemaid clasps or breakaway connectors simplifies troubleshooting without damaging components.

In advanced terms, VCC droops under load while GND elevation increases impedance—both dynamic behaviors that skilled designers anticipate. But for beginners, the defining lesson is elegantly simple: treat VCC as the upward drive, GND as the stable return.

Secure connections at both ends with firm, clean contacts. This disciplined approach forms the bedrock of all successful breadboard experiments.

Ultimately, VCC and GND are more than technical jargon—they are the invisible conductors of circuit logic.

Mastering their identification, placement, and connection on a breadboard empowers new electronic creators to transition from theory to tangible, functional prototypes with confidence. Done right, every powered row on a breadboard becomes a step toward reliable innovation—one properly joined wire at a time.

In a field where precision shapes possibility, VCC and GND are not just parts of a circuit—they are the pulse that brings electronics to life, one breadboard connection at a time.

Related Post

Talk Pertains Kelly Ripa: Is a Newborn Anticipated?

Kai Cenat & Diddy: Are They Neighbors? The Truth Behind the Rumors

Clara Bryant: Hollywood’s Rising Star Redefining Craft and Charisma

Roman Reigns Reacts To Young Fan Demanding To Be Acknowledged