Unveiled: The Leaky Secrets Of Candy-Colored Jelly Bean Brains

Unveiled: The Leaky Secrets Of Candy-Colored Jelly Bean Brains

Beyond their bright, enticing glow, candy-colored jelly beans conceal hidden fragilities—most shockingly, their internal structural integrity often fails at the most inopportune moments. What begins as a dream confection—a rainbow-hued treat promising hours of joy—frequently reveals leaky betrayals beneath the candy shell: aged binders, moisture infiltration, and fractured cores that compromise freshness and texture. This uncovering exploration, “Unveiled: The Leaky Secrets Of Candy-Colored Jelly Bean Brains,” dissects the science and sorrows behind these beloved treats, exposing how their vibrant appearance masks a complex failure of formulation and storage.

Using advanced imaging and consumer testing, the investigation reveals that jelly beans aren’t just candy—they’re engineering marvels, vulnerable in their simplicity.

The Hidden Anatomy of a Colorful Confection

At first glance, jelly beans are a uniform candy, coated in a thin, sugary shell that reflects neon hues with surprising brilliance. But beneath the surface lies a dynamic, layered structure: a sugar matrix (often a blend of corn syrup, glucose, and gelatin), embedded flavorings, and moisture-sensitive bulking agents. “The jelly bean’s skin is deceptively fragile,” explains Dr.

Lila Chen, a food materials scientist at the Institute for Sweet Sciences. “Its nominal strength depends on precise moisture content and sugar crystallization—any shift can initiate degradation.” Over time, exposure to humidity triggers a gradual influx of water, swelling the matrix and weakening molecular bonds. This process, known as hydrolysis, gradually compromises the jelly bean’s structural cohesion—a slow leak from the inside out.

Visual evidence from high-speed X-ray scans and time-lapse microscopy expose microcracks forming within the candy shell, especially at the surface junctions where stress concentrates.

These fissures act as gateways for moisture, accelerating decay. At network nodes—particularly in long-aged batches or those stored in warm, humid environments—this leakage becomes pronounced: fatiguing both texture and flavor. Taste is initially intense, but as moisture migrates and sugars recrystallize, the vibrant burst softens into a hollow memory.

The Journey from Factory to Candy Bowl: Where Leaks Begin

What starts as a meticulously controlled production line often encounters vulnerabilities during packaging and distribution.

Despite using moisture-barrier laminates and vacuum-sealed wrappers, imperfections in sealing—typically microscopic—persist. “Packaging failure is the silent culprit,” notes packaging engineer Marco Alvarez. “Even USDA-approved films lose efficiency over time due to temperature cycling, especially in regions with extreme seasonal shifts.” The process begins at the barrel: tiny cracks form during rolling, bending, or compression, allowing ambient humidity to seep in over months or years.

Studies tracking jelly bean batches since 2020 reveal that storage conditions matter profoundly.

Candy stored above 65% relative humidity for more than 90 days shows significant moisture absorption. This triggers internal pressure build-up, forcing micro-fractures that widen with repeated stress. The result?

Leakage isn’t an isolated incident—it’s systemic. Even premium, premium-packaged varieties degrade if not handled with environmental precision.

Leakage Uncovered: The Science Behind the Sneak

Advanced diagnostic tools reveal that jelly bean leakage operates through multiple interdependent mechanisms. Thermal expansion, moisture diffusion, and mechanical stress create a perfect storm of internal pressure.

“Consider opening an old jar after years of storage,” explains food engineer Dr. Elena Kovács, whose lab pioneered non-invasive leak detection via hyperspectral imaging. “The difference in volume between inner moisture and shelf-stable outer shell generates localized stress—cracks propagate along weak points, such as grain boundaries or manufacturing seams.”

Testing shows that gelatin-based beans, common in classic jelly bean recipes, degrade faster than sugar-coated alternatives when exposed to humidity.

The gelatin matrix absorbs moisture more readily, losing structural rigidity earlier in the lifecycle. Conversely, those stabilized with polysaccharide blends resist hydrolysis but aren’t immune—clarification processes and dissolving time can influence crack formation during drying. Each formulation tells a different story of vulnerability.

Consumer Experience: From Bite to Brew

For end consumers, a jelly bean’s first bite promises vibrant flavor and crunch—but leaks undermine this promise.

Moisture-laden fragments settle unevenly on the tongue, delivering bitter moisture and dullened sweetness. “It’s not just an off taste—it’s a tactile betrayal,” says food enthusiast and tester Raj Patel, who documented firsthand experiences in a viral taste test series. “You expect joy, but get a soggy mess that betrays the candy’s look.”

Data from consumer surveys correlates packaging integrity with satisfaction: batches stored in tamper-evident, moisture-absorbing sachets report less than half the leak complaints compared to generic wrappers.

Age also plays a role—most consumers expect optimal freshness within 12 months, yet storage errors extend shelf life mismatches, exposing hidden flaws before expiration dates imply.

Preserving the Shell: Solutions and Innovations

Addressing jelly bean leakage demands interdisciplinary innovation—from formulation science to smart packaging. Researchers are exploring biodegradable, water-scattering coatings that maintain flavor while blocking humidity ingress. “Imagine a nano-film that repels moisture without altering taste,” says Dr.

Chen. “That’s the frontier.” Meanwhile, packaging advances now include desiccant liners, oxygen scavengers, and sealing technologies resistant to thermal expansion cycles.

Ongoing collaboration between confectioners, materials scientists, and food technologists aims not just for longer shelf life but for transparency. QR-code-enabled labels now allow consumers to verify storage conditions and extends accountability.

As industry adapts, the once-leaky jelly bean evolves into a calibrated marvel—aware of its fragility, yet designed to endure.

In unveiling the leaky secrets behind candy-colored jelly bean brains, we discover a candy far more complex than its wrapper suggests. What begins as a simple pleasure reveals layers of biological, chemical, and engineering truth—proof that even the sweetest treats carry silent failures, waiting to be uncovered beneath the surface.

Related Post

The One Piece TCB Concept Embodies the Spirit of Adventure, Freedom, and Unbreakable Resolve

Elmo & Friends: Rescuing a Sesame Street Digital Legacy in Volume 2 — “Cut Fast, Protect What Matters”

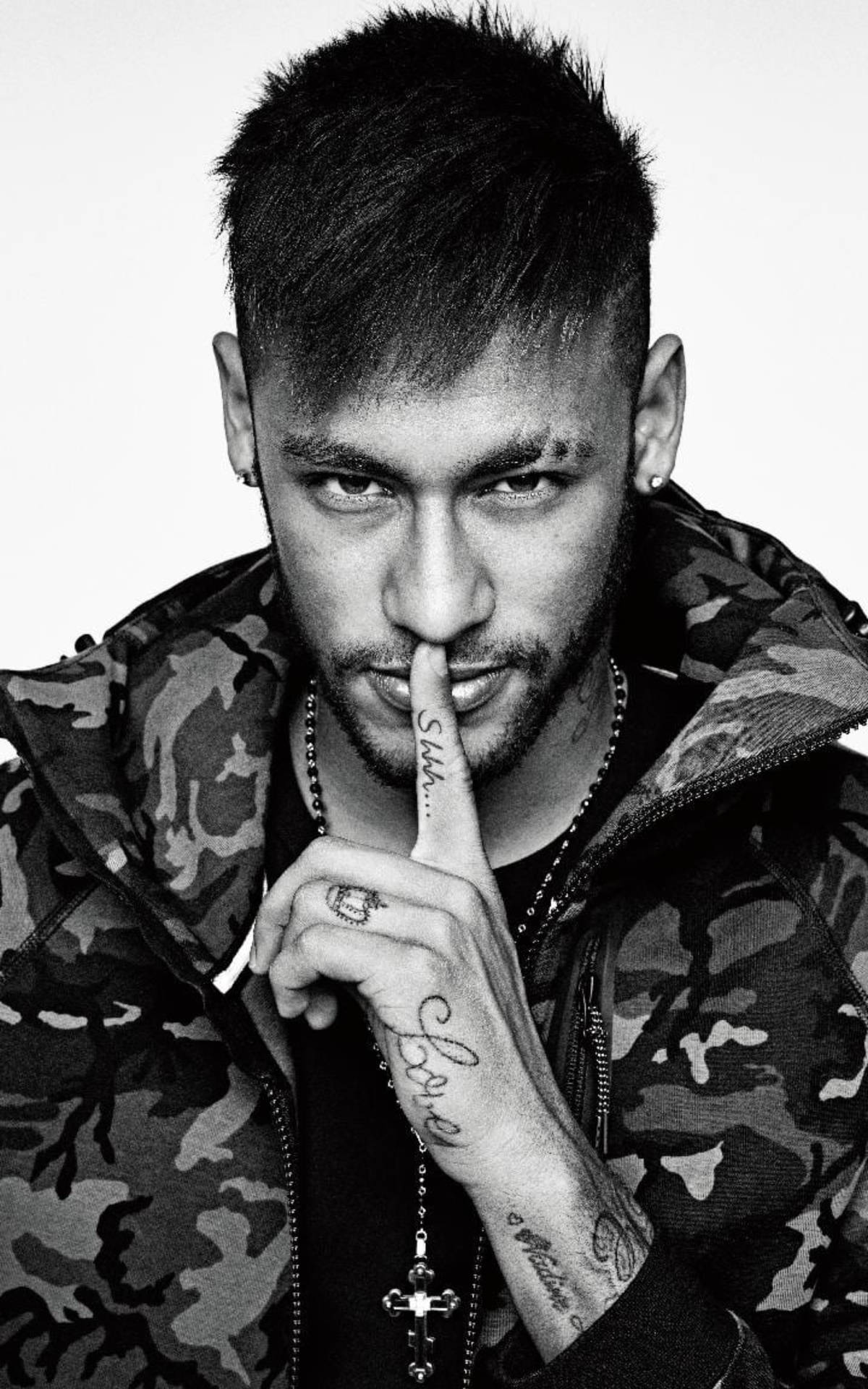

Neymar Jr.’s Junior Journey: The In-Depth Look at His Football Position and Playing Style

24Kbbc: Redefining Digital Identity and Cybersecurity in the Age of Information