Toyota Ae92 Trueno GT Z: Decoding Performance, Repairs, and Restoration Mastery

Toyota Ae92 Trueno GT Z: Decoding Performance, Repairs, and Restoration Mastery

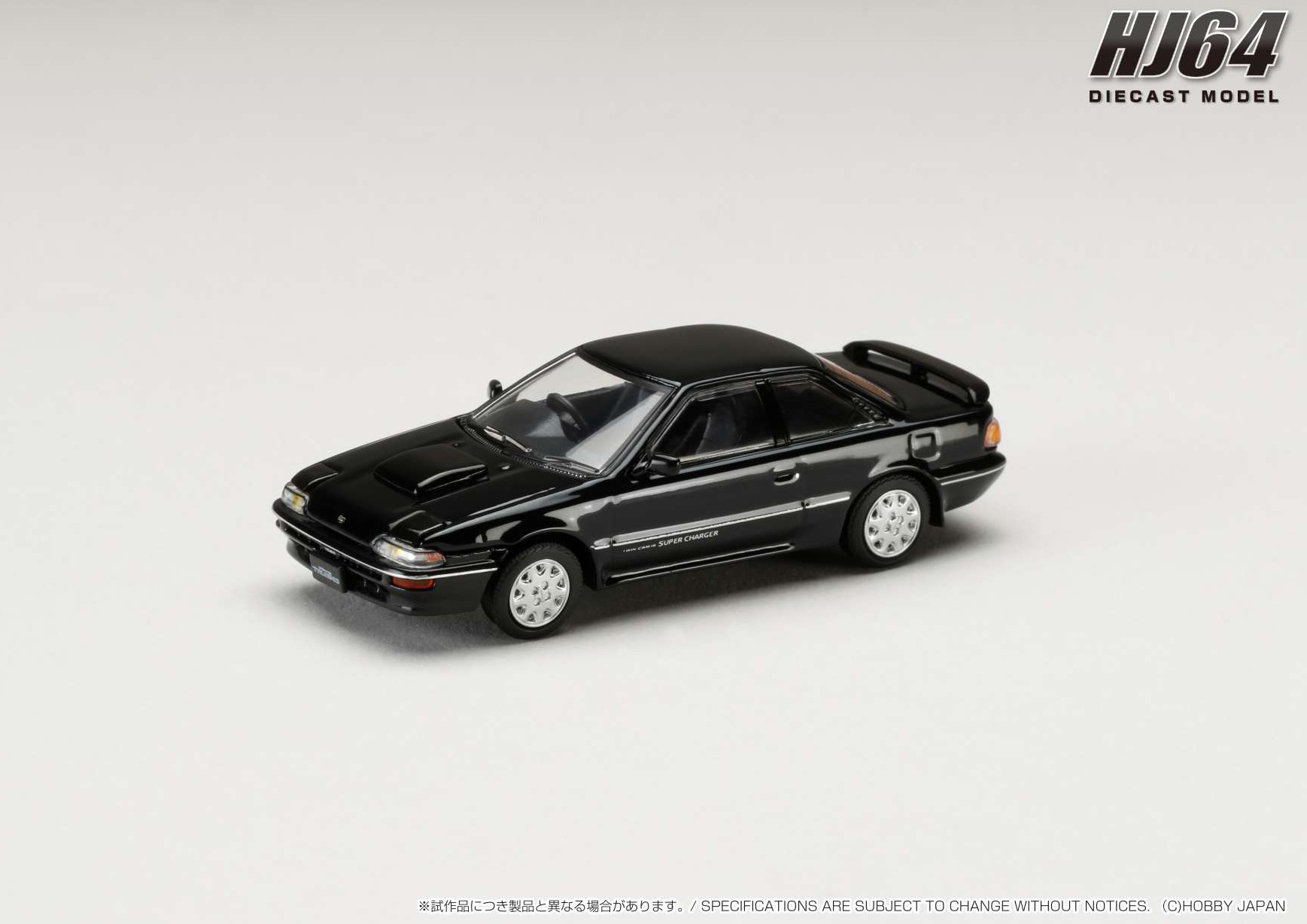

The Toyota AE92 Trueno GT Z stands as a cult classic among Japanese sports sedan enthusiasts—paired with a high-output 2JZ-GTE engine, razor-sharp handling, and timeless styling, this benchmark from the late 1990s continues to command attention in restoration circles and performance workshops. Built on the AE92 platform shared with the Levin, the Trueno GT Z fused precision engineering with driver engagement, making it a revered upgrade path for collectors and tuners alike. Yet, maintaining and repairing these high-revving machines demands specialized knowledge—especially when navigating the complexities of repeating common faults, sourcing rare components, and executing authentic restorations.

This comprehensive overview dissects the key specifications, common repair challenges, and specialized techniques essential to preserving the AE92 Trueno GT Z’s mechanical and cultural legacy.

The core of the AE92 Trueno GT Z’s performance lies in its 3.0-liter inline-six 2JZ-GTE engine, a derivative of the renowned 2JZ unit celebrated across Toyota’s Golden Age. Developed from the legendary MR2 2JZ, this naturally aspirated powerplant delivers 252–275 kW (338–375 hp) depending on tuning ethics and mechanical integrity.

With a redline exceeding 8,000 RPM and a peak torque output hovering near 370 Nm, the engine responds with crisp, linear power delivery—ideal for tempo-driven driving and track sessions. Engine internals remain robust but require meticulous maintenance: valve train components, in particular, are vulnerable to wear, especially under extended high-RPM conditions. Timing belt replacement intervals are non-negotiable; failing to adhere to the manufacturer’s schedule often results in catalytic damage or catastrophic failure.

Key Technical Specifications: Performance Meets Practicality

Behind the curtain of raw power, the AE92 Trueno GT Z’s architecture prioritizes balance and refinement.Key metrics include: - Engine displacement: 2,997 cc (1,830 cc per bank) - Bore × stroke: 86.0 mm × 84.8 mm - Compression ratio: 10.3:1 - Wet-sump lubrication with dualオイル펌프 circulation - Transmission: 5-speed manual—locked behind the 4S tr桿, delivering sequential responsiveness - Ground clearance: 122 mm, enhancing front-end neutrality - Trial height: ~80 mm, facilitating aggressive cornering These specs collectively make the GT Z a driver’s car through and through. The 5-speed manual remains a preferred gearbox for purists seeking engagement; automatic variants, while convenient, often dilute the proportional feel—especially under heavy deceleration. Weight distribution, fairly optimal at roughly 52:48 front-rear, supports stable handling, though gullwing-style lifters and sway bar links frequently require reed adjustments to eliminate feedback.

While the enduro heritage of the AE92 platform often steals the spotlight, the GT Z’s chassis demands careful attention during repairs. The unibody structure, though rigid, reveals subtle flex at high bias angles—particularly noticeable during hard cornering or full-throttle entry. Modern restoration efforts often involve strategic reinforcement using aluminum rods or custom mounts, preserving originality while enhancing durability.

Suspension components like control arms, bushings, and sway bars are commonly replaced; OEM-spec Toledo dampers paired with OEM-style bushings deliver unfaulted performance. Strut mounts frequently suffer stress fractures, necessitating full inspection—swapping out worn parts prevents premature bearing wear in the stabilizing arms.

Braking performance presents another critical maintenance focus. The GT Z comes standard with front disc brakes measuring 270 mm paired with 6-piston calipers—adequate in many scenarios, but track drivers and heavy lifters often upgrade to 350 mm front discs with collared slabs and upgraded calipers.

Anti-lock systems, absent on original models, are increasingly installed to improve temporary braking friction. Rotors must be replaced in pairs, ensuring concentricity and optimal heat dissipation; warped or unevenly worn components accelerate pad deterioration and compromise pedal feedback.

Fuel and Ignition: Precision Engineering in Motion

Fuel delivery in the 2JZ-GTE relies on a BOSCH L-Jetronic system integrated with a clean, vacuum-regulated injector set.Common repairs involve injector cleaning or replacement due to carbon buildup—common after prolonged toe-in coasting or improper tuning. Fuel pressure regulators require attention: sticking valves or clogged passages alter equilibrium, affecting both torque curves and emissions compliance. Fuel pressure typically sits around 45–50 psi, and deviations warrant pneumatic regulator replacement with factory-calibrated settings.

Ignition tuning is equally pivotal. Original spark plugs, typically thermally tracked from NGK BTEL20P-S1, fire consistently at 430–460°C, producing sharp, clean arcs. Malfunctioning coils, clinics with unclean connection pads, or failing wires degrade injector pulse angles, leading to misfires, hesitation, or rough idling.

Tuning must respect original PW spec—retuning with modern ignition coils risks altering flashover points and stifling engine response. Distributor cap and rotor assemblies, prone to carbon tracking, should be replaced every 80,000 km to maintain consistent spark intensity.

Electrical system integrity is non-trivial.

The GT Z’s CDI-based ignition benefits from periodic capacitor replacement—aged units cause egs to falter under load. Fault codes buried in the Powertrain Control Module (PCM) require OBD-II scanning; common stored trouble codes include P0335 (RPM sensor circuit) and P0230 (catalyst low efficiency), both frequently originating from slave actuator wear or exhaust leaks upstream. Wiring harnesses, especially near exhaust heat zones, suffer from chafing and corrosion—necessitating heat-shrink replacement and secure routing with foam pipe boots.

Restoration and Custom Builds: Merging Originality with Performance

For collectors and restorers, the AE92 Trueno GT Z represents a rare fusion of factory purity and customization potential. Authentic builds prioritize OEM parts—6-bolt wheels (mainly 16-inch code 879693-303), factory-style body clips, and iron-clad engine internals. OEM-spec vibration dampers, when properly installed, eliminate inconsistencies in rear axle shimmy, restoring satisfying NVH balance.Custom upgrades typically center on suspension stiffness and aesthetic enhancements. Custom coilovers with adjustable damping bolster track readiness, tuning ride height and roll stiffness. Roll cages, while altering original proportions, enhance safety and enable lower center of gravity for aggressive driving.

Inside, gauge panels from Derek Ryan or Roots Racing integrated with manufacturer-forged buckles preserve authenticity while elevating usability.

One of the GT Z’s enduring strengths lies in its repairability; widespread parts availability from JDM suppliers and discreet third-party fabricators ensures accessibility. However, tunnels often require custom cutouts for extended exhaust headers or forged intake manifolds—labor-intensive tasks demanding coordinate-matching precision.

Gearbox mounts frequently develop flex after heavy lifting; bellhousing bolt torque verification and stay back pin replacement prevent long-term misalignment. Bearings in transfer cases and drive axles exhibit early wear under persistent high-torque reliance—marked by delayed gear engagement or grinding feedback.

Modern tuning methodologies—whether standalone firmware upgrades or calibrated D Differences in transparencies—require cautious calibration to avoid catastrophic engine damage.

While wide-open throttle response delights purists, reliability must anchor all modifications. The 2JZ-GTE’s selective attention points—like the camshaft yield at 7,000 RPM or specific pinpoint valve spring torsional fatigue—demand 억 정기ött “Inside the exhilarating world of the Toyota AE92 Trueno GT Z, unmatched performance converges with timeless design—yet preserving its legacy demands mastery of mechanical nuance, precision repairs, and an unwavering commitment to authenticity. From diagnostic rigor to thoughtful restoration, every bolt tightened and circuit traced honors the engineering brilliance born in the late 1990s.” ペ

Related Post

Diving into Divinity: The Enduring Legacy of Vrindavan Banke Bihari

Earliest Laptop: The Quiet Pioneer That Set the Pace for Modern Computing

The Rise of Robux Power: How Www.4Koy.Com Dominates the Virtual Value Economy

The Enduring Legacy Embodied: The University of Michigan Logo in Academic Excellence