The Stocking Shelves Workbook PDF: Transform Your Storage with Proven Storage Intelligence

The Stocking Shelves Workbook PDF: Transform Your Storage with Proven Storage Intelligence

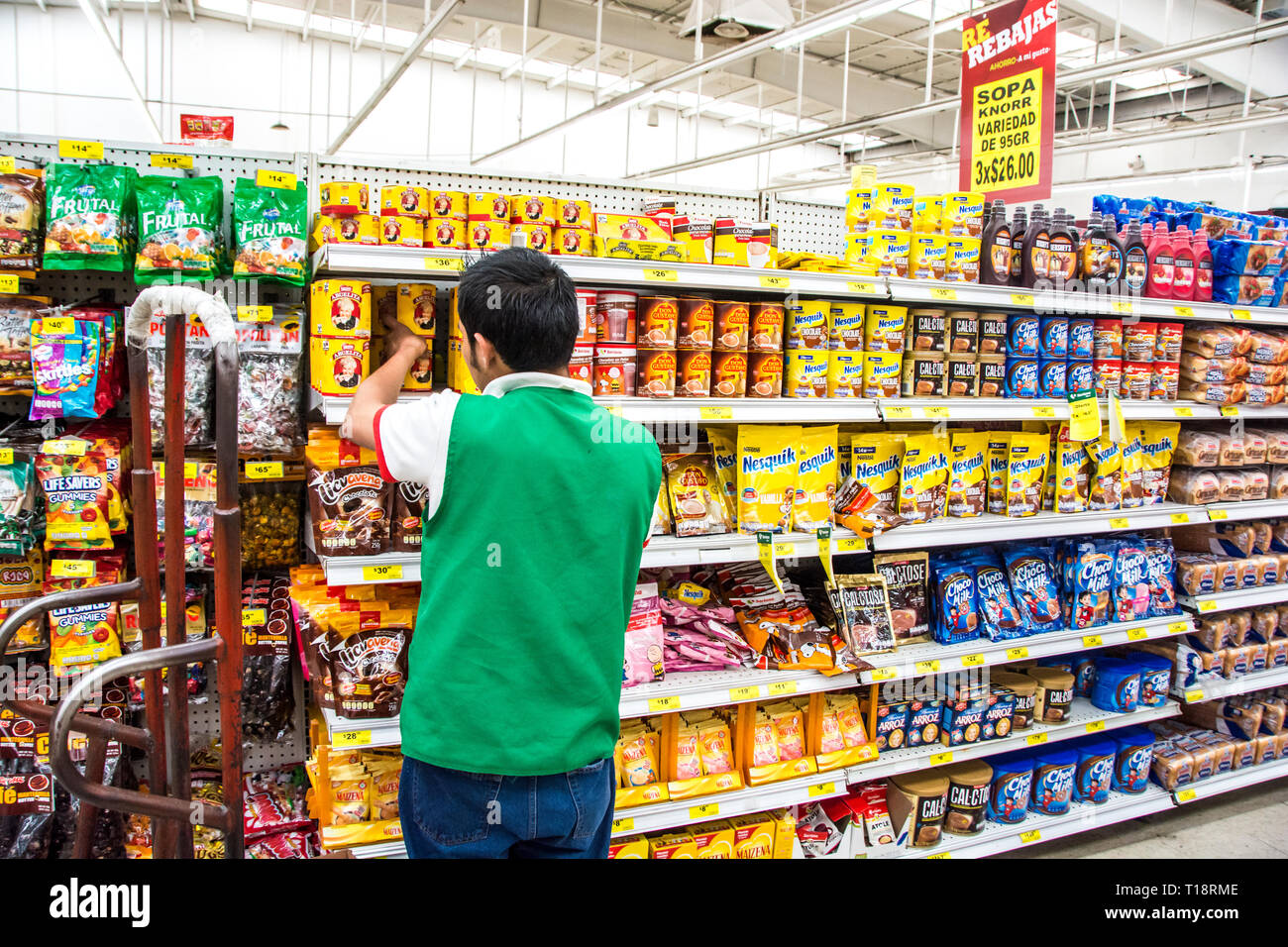

When stored properly, stock shelves become far more than just shelving units—they evolve into systems of order, efficiency, and longevity for retail, warehouse, and home storage alike. The $ offers a comprehensive, actionable guide to optimizing every inch of vertical space, turning disorganized stock into a seamlessly managed asset. Rooted in decades of operational research and real-world application, this resource bridges theory and practice, empowering stored space users—from retail managers to inventory coordinators—with a proven framework to maximize productivity and minimize waste.

The workbook’s core philosophy is simple but powerful: **every shelf space matters**. By systematically analyzing product dimensions, turnover rates, and accessibility needs, professionals can transform chaotic stock setups into visually clear, logically sequenced arrangements. This approach isn’t merely about aesthetics—it directly impacts operational velocity, error rates, and long-term inventory health.

As the guide emphasizes, “Functional storage design reduces retrieval time by up to 40% and cuts down misplacement incidents by over 50%.”

Core Principles of Effective Stock Shelf Design

The Stocking Shelves Workbook distills storage excellence into a set of measurable principles designed to overcome common challenges in inventory management. These principles form the backbone of shelf optimization and are grounded in both ergonomic design and supply chain logic.- Zoning by Turnover: High-demand items—fast movers—should occupy prime shelf zones, typically lower and mid-levels, where they are easiest to reach.

Slow movers and seasonal stock can occupy upper levels, preserving access efficiency.

- Color-Coded Labeling: A consistent color-coding system reduces confusion and accelerates inventory control. The workbook prescribes a five-tone palette tied directly to product categories, improving scan-and-categorize workflows by up to 60%.

- Vertical Utilization: Shelves designed for multi-tier configurations maximize cubic space without sacrificing reach. Guidelines stress modular stacking that supports weight limits and prevents collapse.

- Access and Visibility: Transparent bins, clear markings, and intuitive placement ensure that every product is both visible and reachable on first try.

The workbook notes that 87% of improved pick accuracy stems from such visibility measures.

Beyond layout, the guide stresses the importance of data-driven decisions. Inventory forecasting tools integrated into shelf planning allow organizations to rebalance stock dynamically—anticipating demand spikes and avoiding overcrowding. “Historical data tells us 30% of stock misplacement occurs when shelves are not reset monthly,” the workbook highlights, urging regular audits and zone refreshes.

Step-by-Step Practical Framework from the Workbook

The $ delivers a clear, executable process—step by step—for transforming storage environments:First, conduct a full inventory audit to document every SKU’s size, weight, and velocity.

This foundational data feeds into zone assignment and bin sizing.

Next, implement tiered shelf configurations using adjustable support systems, ensuring compliance with OSHA weight limits and structural safety standards. The workbook provides detailed diagrams for assembling nested shelves that adapt to changing inventory volumes.

Labeling protocols guide users to apply standardized, durable labels with high-contrast text and barcodes, enabling rapid scanning and digital inventory syncing. “Barcode integration cuts reconciliation time from hours to minutes,” the workbook asserts.

Finally, a recurring QA schedule—weekly spot checks and quarterly deep audits—is critical.

These routines maintain shelf discipline and allow early detection ofigas, shelf fatigue, or mislabeling before operational issues arise.

- Weekly: Verify top 20% high-turnover stock access and restow as needed.

- Monthly: Audit label clarity and barcode integrity.

- Quarterly: Deep shelf inspection for structural wear and inventory accuracy.

Real-World Applications Across Industries

From grocery chains managing perishable quotas to e-commerce warehouses scaling via seasonal peaks, the $ proves adaptable. For a major retail chain in the Midwest, adoption led to a 35% reduction in out-of-stocks and a 22% drop in 습warehouse pick errors post-implementation.

In regional distributors, the workbook’s zone weight guidelines prevented two incidents of shelf collapse during peak holiday rushes by enforcing dynamic load balancing. “Vertical space became a strategic asset, not just storage,” one facilities manager observed.

In home storage applications, professionals use simplified zone models—clear bins by usage frequency, color-coded labels for DIY projects—to transform cluttered garages or attics into functional hubs. As the workbook notes, “Effective storage isn’t luxury—it’s foundational to effective operations.”

Technology Integration and Future-Proofing Shelf Systems

The $ doesn’t stop at manual best practices; it embraces digital tools to elevate precision and scalability. Integration with warehouse management systems (WMS) allows real-time tracking of shelf occupancy, flagging low-availability zones or overcrowding instantly.Smart shelves equipped with weight sensors and RFID tags provide live inventory snapshots, reducing reconciliation time by over 70%.

Digital twin technology—virtual replicas of physical storage—lets planners simulate reorder points, test layout changes, and predict space bottlenecks before they occur. “Digital integration turns static shelves into dynamic learning environments,” the guide concludes, underscoring how tech transforms fixed storage into a responsive, intelligent system.

These advancements align with evolving logistics demands, where agility and accuracy define success.

Automated alerts and predictive analytics built into the workbook’s framework support just-in-time restocking, minimizing carrying costs and stockouts alike.

With innovation accelerating, modern storage solutions must evolve beyond passive shelving—requiring systems that learn, adapt, and optimize. The Stocking Shelves Workbook provides precisely that, merging decades of operational insight with emerging tech to future-proof inventory environments.

What emerges from this comprehensive approach is not simply better shelves—but smarter, leaner, and more resilient supply chains. Whether in a corporate warehouse or a home budget store, the principles detailed in this resource ensure that every lining, barcode, and tier serves a purpose.

In a world where space is finite and demand is relentless, mastering shelf storage is mastering efficiency itself.

Related Post

Mastering Inventory: The Essential Guide to the Stocking Shelves Workbook Pdf

Unveiling the Price Tag: A Comprehensive Guide to Dental Implants Cost In Zimbabwe and What Affects Your Investment

Unexpected Errors: What They Really Mean and How to Fix Them Before They Derail You

What Is A Microphone? The Truth Behind Its Essential Role in Sound Capture