Steel Structure Design with ETABS: A Practical Guide to Precision Engineering

Steel Structure Design with ETABS: A Practical Guide to Precision Engineering

In the evolving landscape of structural engineering, steel remains one of the most versatile and demanding materials, enabling the construction of high-performance, safe, and aesthetically bold buildings. To harness its full potential—especially in complex multi-story designs—engineers increasingly rely on ETABS, a powerful software platform tailored specifically for steel and reinforced concrete structural analysis and design. This practical guide demystifies how ETABS transforms steel structure design from conceptual sketches into rigorously verified, code-compliant models—offering clarity, efficiency, and confidence throughout the engineering lifecycle.

ETABS, an acronym for Extended Three-Dimensional Analysis of Loads and Stresses, is a dynamic modeling and analysis tool developed by CNDI, now part of Autodesk. Unlike traditional hand calculations or basic CAD programs, ETABS enables engineers to create complete 3D structural models that capture the full complexity of steel systems—from frame frames and trusses to moment-resisting frames, braced frames, and composite configurations. As structural engineer Dr.

Laura Chen notes, “ETABS bridges the gap between conceptual design intent and performance-based engineering by allowing engineers to simulate real-world loads, material behaviors, and dynamic responses within a single integrated environment.”

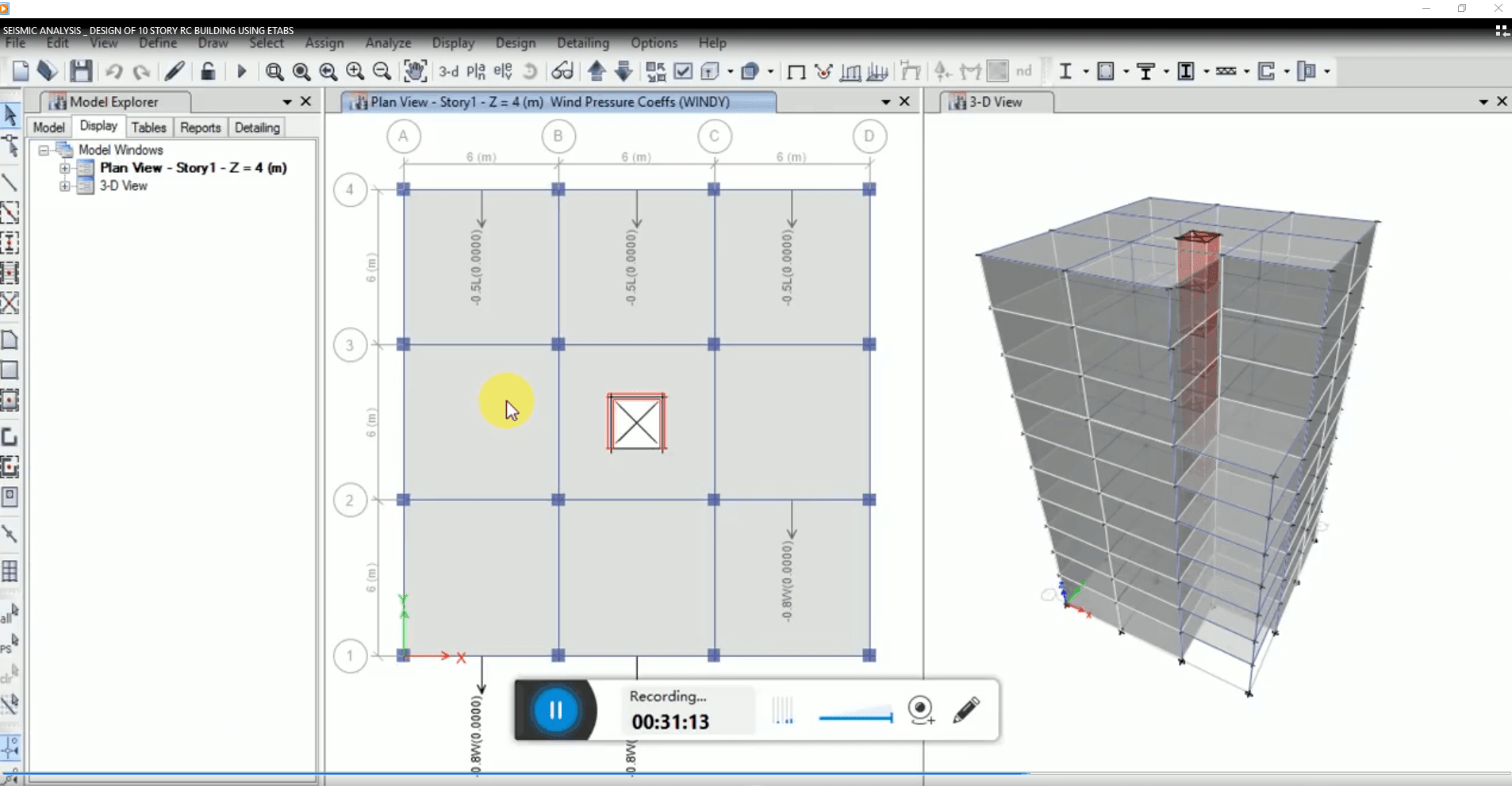

Key Strengths of ETABS in Steel Structure Design: - Comprehensive 3D modeling capabilities support accurate representation of complex geometries, connections, and system behaviors. - Advanced material and section libraries include a wide range of steel grades, welding details, and yield criteria compliant with global codes such as AISC, Eurocode, and IS 800. - Dynamic analysis tools evaluate seismic response, wind loads, and vibration—critical for high-rise and long-span steel structures.

- Automated checks against code provisions reduce human error and accelerate design review cycles. - Seamless integration with AutoCAD and Revit enables smooth transition from design to documentation.

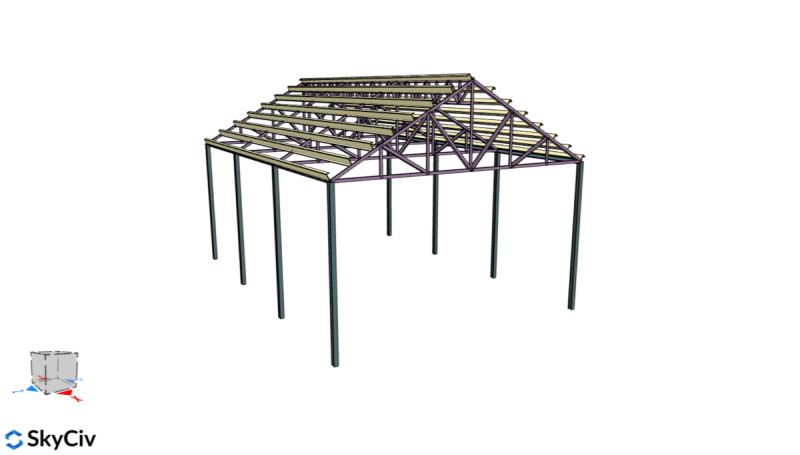

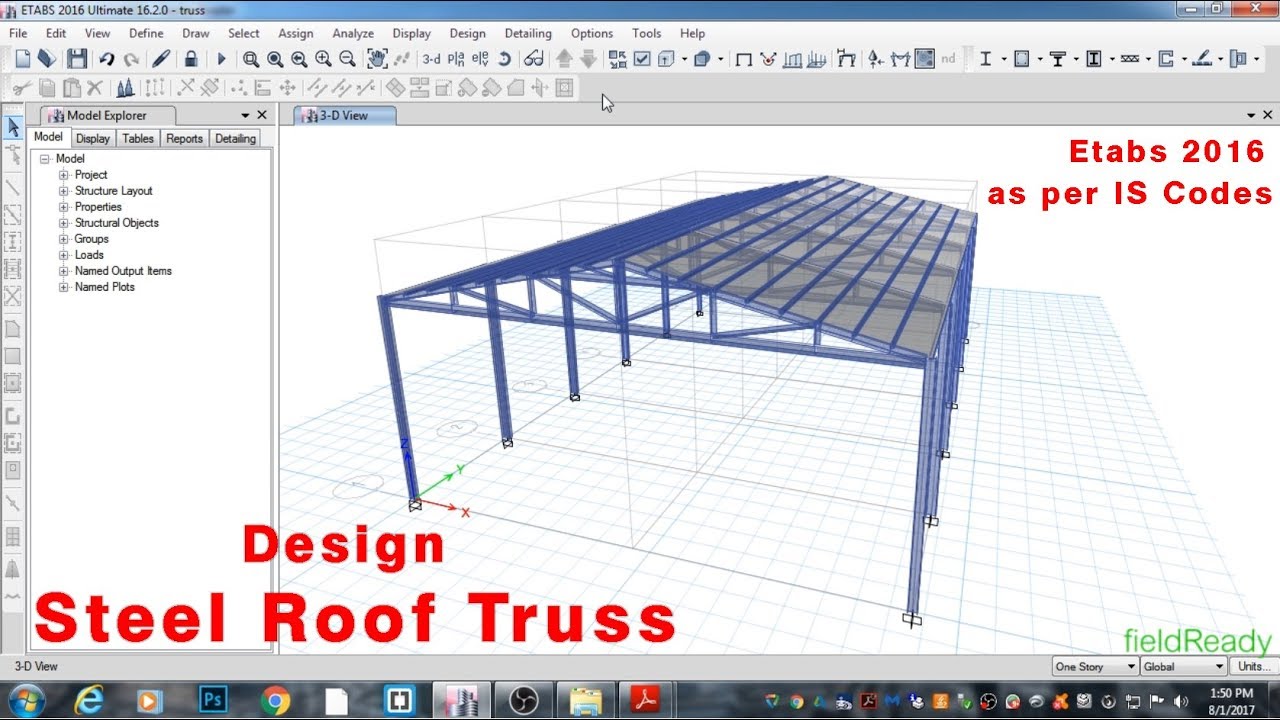

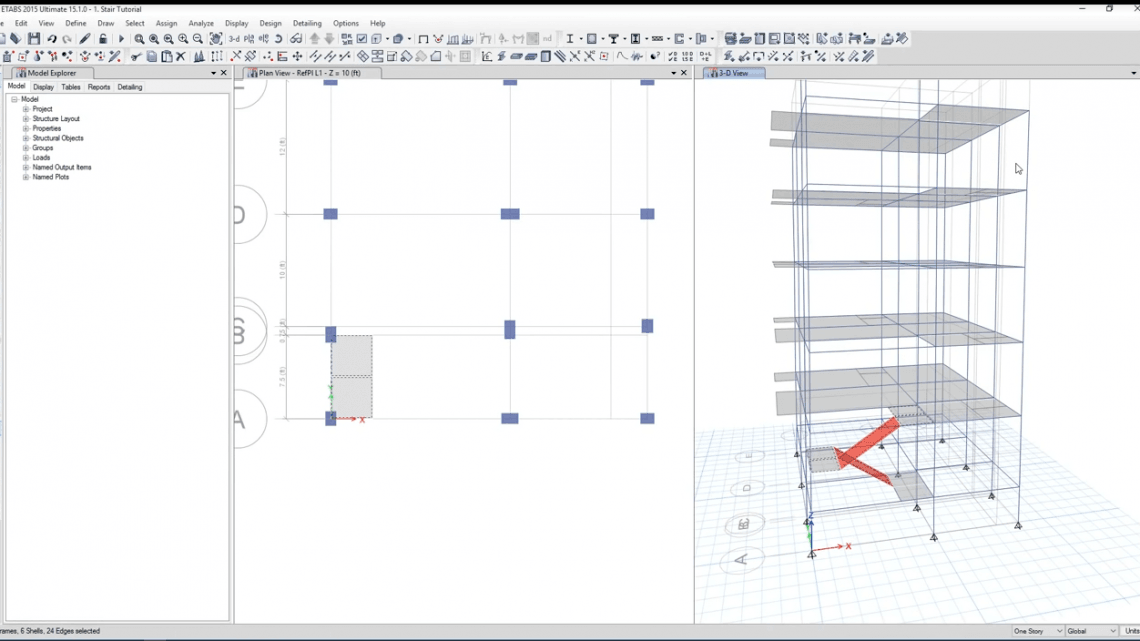

The Core Workflow: From Steels to SteelFrame Models Designing steel structures with ETABS begins with translating architectural and load resolve into a logical structural system.

Engineers break down the building into discrete elements—columns, beams, diaphragms, shear walls—and assign material properties and section geometries. ETABS users leverage predefined steel section libraries (e.g., ASTM A36, AH36, S235) and define beam-column joints, connection types, and stiffness constraints. This structured modeling process ensures every component’s behavior is accurately captured.

Each phase of modeling requires careful attention: 1. **Basic Model Setup**: Defining elevations, grid spacing, load combinations, and support conditions. 2.

**Geometric and Section Input**: Importing or defining geometry via CAD, assigning Section 5 or Section 6 profiles with detailed strength data. 3. **Load Assignment**: Applying dead, live, wind, snow, and seismic loads per design codes, with stage load capabilities for time-dependent analysis.

4. **Analysis Execution**: Running static, dynamic (modal, harmonic), and nonlinear time-history analyses—essential for verifying performance under extreme events. 5.

**Results Interpretation**: Extracting deflections, internal forces, stress distribution, and buckling checks to validate design adequacy.

Code Compliance and Performance Validation Steel steel construction must adhere to stringent national and international codes. ETABS embeds these standards directly into its analysis framework—enforcing AISC 360 for structural stability, Eurocode 3 for ductile behavior, and IS 800 for reusable steel (IRC) requirements.

“One of ETABS’s most valuable features is its ability to auto-check design compliance,” says practicing engineer Raj Patel. “From ultimate limit state (ULS) to serviceability limit states, the software flags violations in real time, preventing costly rework long before fabrication begins.” The tool also supports performance-based engineering, allowing nonlinear static and dynamic simulations to assess drift capacity, buckling modes, and fatigue life—critical for sustainable and resilient design in seismically active regions or high-wind zones. With ETABS, engineers generate detailed reports and 3D visualizations that communicate technical findings effectively to clients, contractors, and regulators.

Real-World Applications and Case Studies In practice, ETABS proves indispensable across diverse steel applications—from low-rise commercial buildings to iconic skyscrapers. Consider a recent mixed-use tower in Singapore where ETABS enabled the design team to optimize column spacing and member sizes, reducing steel consumption by 7% without compromising safety. The software’s dynamic analyzers simulated typhoon-level wind loads, revealing previously undetected torsional responses that prompted critical early adjustments.

For bridge structures, ETABS’ specialized bridge module streamlines truss and girder modeling, accounting for axial loads, thermal effects, and fatigue from traffic cycles. Git between design phases, performance data inform material selection and maintenance planning, extending asset lifecycle.

Overcoming Challenges with ETABS While ETABS offers extraordinary capabilities, mastery requires discipline.

Overly complex models invite interpretation errors; ignoring material anisotropy or connection stiffness can lead to inaccurate load paths. The key is iterative refinement—balancing fidelity with computational efficiency. Training resources, including Autodesk-certified courses and model libraries hosted by structural consulting firms, accelerate proficiency.

The integration of ETABS into steel design is not just a technological upgrade—it’s a paradigm shift toward data-driven, predictive engineering. By transforming abstract concepts into verifiable, high-fidelity models, ETABS empowers engineers to innovate with confidence, delivering safer, lighter, and more sustainable steel structures. As the built environment grows ever more complex, ETABS stands as a cornerstone tool for modern structural practice—where precision meets progress.

Related Post

January 17 Tyu♌: The Enigmatic Month’s Astrological Sign Unveiled