Solid State Electrochemistry: Powering the Future of Energy Storage and Beyond

Solid State Electrochemistry: Powering the Future of Energy Storage and Beyond

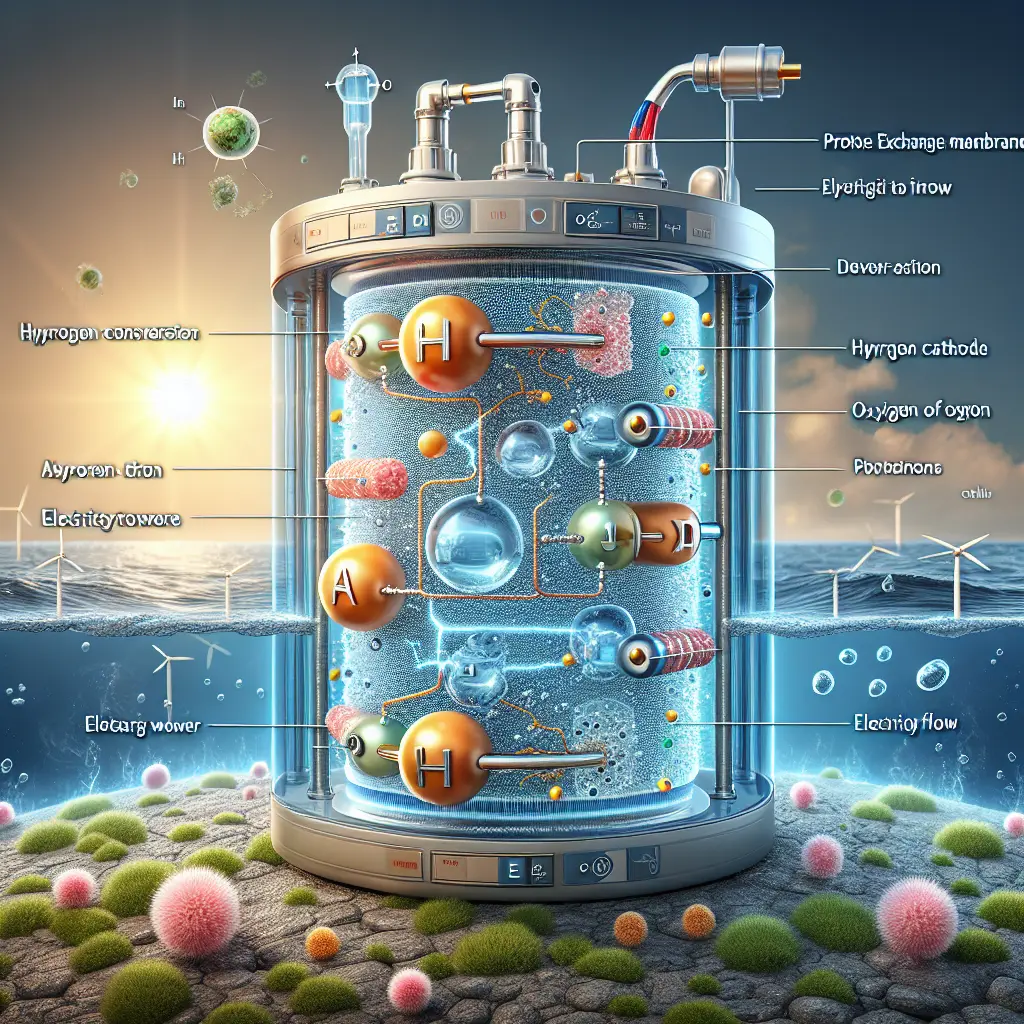

In the silent revolution beneath modern batteries, solid state electrochemistry is redefining energy conversion and storage—enabling safer, more efficient, and longer-lasting technologies that power everything from smartphones to electric vehicles and grid-scale energy systems. Unlike conventional liquid-electrolyte batteries, solid state electrochemical systems replace flammable liquids with rigid, often ceramic or polymer-based solid electrolytes, drastically reducing fire risks while unlocking new performance frontiers. With rapid advancements driven by material science innovation and industrial demand, this field is no longer confined to research labs—it is shaping the next generation of sustainable energy solutions.

At the heart of solid state electrochemistry lies the fundamental challenge of achieving efficient ion transport across solid interfaces while maintaining mechanical and chemical stability. Solid electrolytes—typically oxides, sulfides, or polymers—conduct lithium, sodium, or other ionic charges via vacancy mechanisms, grain boundaries, or polymer chains. “The key breakthrough has been designing materials where ionic conductivity approaches or surpasses that of liquid electrolytes, without the associated safety and volatility,” explains Dr.

Elena Martinez, a senior researcher in battery materials at the Fraunhofer Institute. “This balance enables batteries that operate safely at extreme temperatures and deliver higher energy densities.”

Core Materials and Mechanisms Solid state electrochemical systems rely on a triad of critical components: the solid electrolyte, the electrode materials, and the interfacial engineering that governs electrochemical reactions. Among solid electrolytes, lithium thiophosphate-based sulfides (e.g., Li₆PS₅Cl) and garnet-type oxides (e.g., Li₇La₃Zr₂O₁₂, or LLZO) dominate for lithium-ion applications due to their high ionic conductivity—rivaling or exceeding that of liquid counterparts.

Polymer electrolytes, often based on polyethylene oxide (PEO) blended with lithium salts, offer flexibility and ease of processing but face conductivity limitations at room temperature. Glass-ceramic hybrid electrolytes represent a promising front, blending mechanical robustness with improved ion mobility. Ion transport mechanisms vary by material class.

In ceramic electrolytes, lithium ions migrate through lithium-ion conducting lattice sites, facilitated by defects created during doping—such as aliovalent cations in LLZO. “The crystallinity and grain boundary quality are decisive,” notes Dr. Raj Patel, a materials chemist at MIT.

“Nanocrystalline structures with optimized grain connectivity minimize resistance and allow rapid charge transfer.” In sulfide electrolytes, carriers are thought to jump between sulfur-rich lattice sites, though interfacial decomposition remains a challenge requiring advanced interfacial coatings.

The push for higher energy density drives innovation in electrode design. Traditional graphite anodes give way to lithium metal, promising up to ten times the capacity, but trigger dendrite growth in conventional electrolytes.

Solid state systems suppress dendrites through mechanical stability and constrained ion flux, enabling safer lithium-metal anodes. Simultaneous advancements in cathodes—such as high-voltage layered oxides (NMC, NCA) and sulfur-C complements—leverage solid electrolytes’ tolerance to aggressive electrochemistries. “The synergy between anode, cathode, and solid electrolyte determines overall cell performance,” says Dr.

Marta Delgado, a materials engineer at QuantumScape. “Each component must evolve in concert.”

Manufacturing solid state cells at scale presents formidable challenges. Interface resistance between electrode and electrolyte layers often limits current flow, requiring ultrasonic surface activation, atomic layer deposition, or graded interlayers to restore conductivity.

“Achieving uniform, low-resistance contacts at scale is as critical as material performance itself,” warns Dr. Hiroshi Tanaka, a principal scientist at Toyota’s battery division. Industrial techniques like roll-to-roll processing and thin-film deposition are being refined to scale production while maintaining purity and structural integrity.

Real-world applications are already emerging. Solid state batteries are being piloted in electric vehicles—Toyota plans commercialization by 2027, targeting over 1,000 km range and faster charging. In grid storage, multilayer ceramic batteries offer durable, long-life solutions reducing reliance on fossil fuels.

Medical implants benefit from their safety profile, enabling smaller, longer-lasting pacemakers and neurostimulators. “Solid state electrochemistry isn’t just improving batteries—it’s reimagining energy security,” states Dr. Fatima Khan, a lead scientist at Solid Power.

Current limitations—costly materials, complex fabrication, and uneven durability—persist, but the trajectory is clear: innovation accelerates through interdisciplinary collaboration. Advances in computational modeling accelerate material discovery, while machine learning optimizes synthesis pathways. Regulatory frameworks and industry partnerships are fast-tracking standardization and deployment.

“We’re at a tipping point,” remarks Dr. Luis Ortega of the Department

Related Post

The Weight of Love and Legacy: The Story Behind the Braun Rowland Marriage tributed in Salem’s Obitsforums

Camden America: Redefining Neighborhood Revitalization in Urban America

Cillian Murphy’s Son: A Quiet Portrait of Normalcy in a World of Stardom

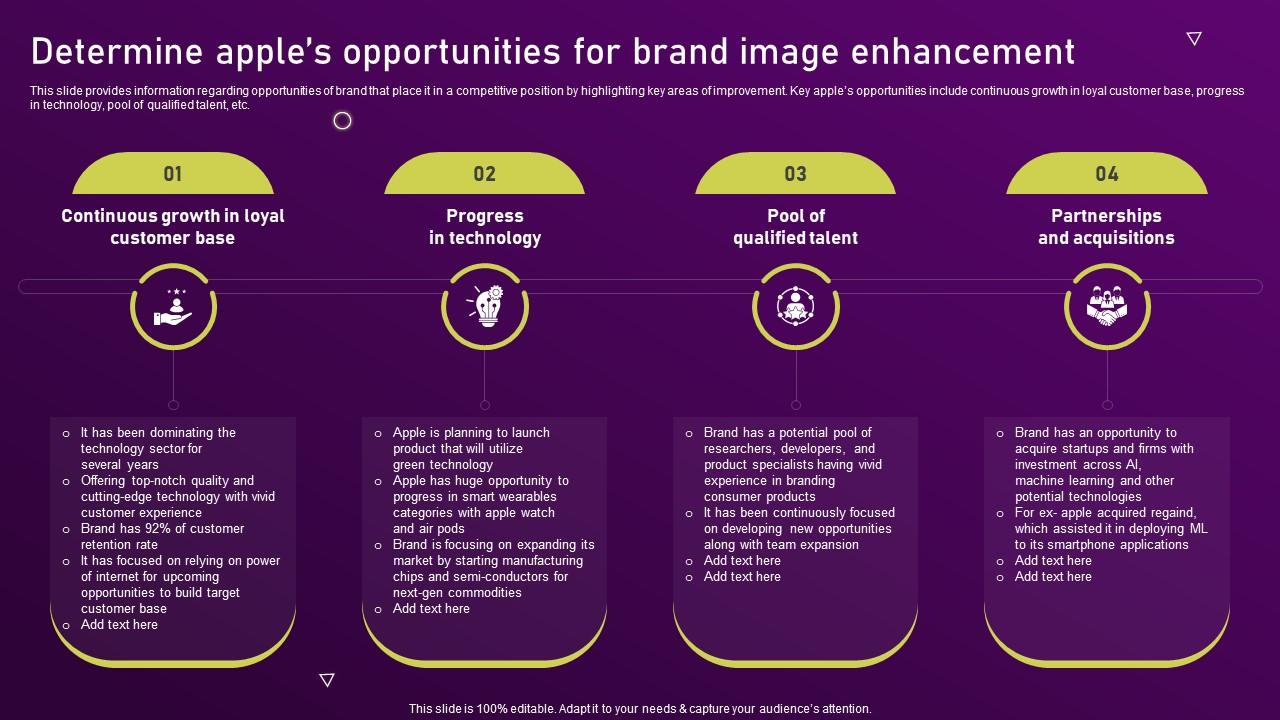

Apples’ Billion-Dollar Empire: Unveiling the Macroeconomics Behind Its Billion-Dollar Net Worth