Porotherm Bricks Not Used in the U.S.: A Hidden Gem in Global Construction

Porotherm Bricks Not Used in the U.S.: A Hidden Gem in Global Construction

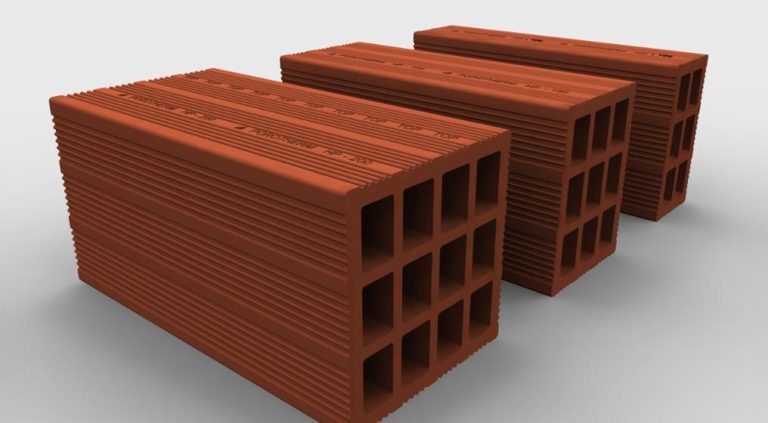

Though rarely seen on American building sites, Porotherm bricks have long held a revered status beyond U.S. borders, where they represent a benchmark in durable, energy-efficient masonry. Unlike standard clay bricks introduced widely in the U.S., Porotherm bricks—developed and perfected by German engineering—bring advanced thermal performance, structural precision, and sustainability, making them ideal for modern climate-conscious construction.

Their absence from mainstream U.S. supply chains reveals a gap in market adoption, yet their proven resilience and environmental profile position them as a transformative alternative waiting for wider recognition.

Originating from Germany and manufactured by the Porotherm Group, these clay bricks stand out not just for their aesthetic warmth and timeless look, but for their engineering excellence.

Constructed from high-fired, porous clay, Porotherm bricks minimize thermal bridging while maintaining impressive compressive strength—often exceeding 10 MPa. “Their internal cellular structure reduces heat transfer, making them inherently energy-efficient,” explains Prof. Reinhard Keller, a structural materials expert at the Fraunhofer Institute for Building Physics.

“This results in lower heating demands and improved indoor comfort, especially in extreme climates.” Unlike conventional porous bricks that may degrade under freeze-thaw cycles, Porotherm’s dense firing process ensures longevity, with many installations lasting over a century without significant deterioration.

What sets Porotherm bricks apart in European and global contexts is their integration with passive design principles. In countries like Germany, Austria, and the Netherlands—where energy codes are stringent and sustainability is non-negotiable—porotherm bricks are standard in passive house projects.

Their consistent dimensions and thermal mass allow for precise wall assembly, enabling optimal performance in super-insulated envelope designs. Each brick typically features a calibrated outer surface for mortar adhesion and an inner core engineered for minimal conductivity, achieving U-values—measuring thermal transmittance—often below 0.6 W/m²K. This exceeds many U.S.-standard masonry products, where typical thermal performance hovers around 1.0 W/m²K or higher.

Environmental credentials further distinguish Porotherm bricks. The production process, though initially energy-intensive, leverages natural raw materials and renewable fuel sources in modern German kilns. On average, producing one Porotherm brick emits 20–30% less CO₂ than conventional fired clay bricks, due to higher combustion efficiency and kiln automation.

“The low specific energy consumption aligns with circular construction goals,” notes Dr. Sarah Müller, sustainability consultant at Bauhaus Umweltservice. “Their long lifespan also means fewer material replacements, reducing lifecycle environmental impact.” Beyond carbon metrics, the bricks are non-toxic and fully recyclable at end-of-life through crushing and reuse in aggregate mixes.

Despite these advantages, Porotherm bricks face steep barriers to entry in the U.S. market. The absence of dedicated manufacturing or authorized distributors means most American contractors rely on imported stock—often via niche importers or specialized building supply firms.

This limits availability, inflates costs, and disrupts supply chain reliability. “Establishing Porotherm in major U.S. markets would require not just logistics but regulatory alignment and code recognition,” says Mark Reynolds, project manager at Coastal Green Builders in North Carolina, who has integrated German masonry solutions into net-zero home designs.

“Current ASTM standards for void ratio and frost resistance don’t always account for porotherm’s unique thermal properties, slowing acceptance.”

Success stories illustrate the bricks’ transformative potential even in fragmented U.S. adoption. At the Oakwood Eco-Community in Vermont, Porotherm bricks form the primary wall system for passive solar homes.

Project engineers report 40% lower heating costs compared to regional brick averages, paired with superior acoustic insulation—an often-overlooked benefit in rural building zones. In Seattle, a mixed-use renovation project showcased Porotherm’s adaptability: retrofitting historic facades while meeting current energy codes required custom mortar formulations and precision laying, yet the outcome exceeded client expectations for both heritage preservation and modern performance.

Industry insiders acknowledge that mainstream U.S.

uptake hinges on bridging knowledge and accessibility gaps. “The bricks’ technical superiority is clear, but market penetration demands education,” says Sarah Fischer, technical lead at GreenBuild Solutions, a firm specializing in sustainable façade systems. “Contractor training, code updates, and localized demonstration plots could unlock broader curiosity.” Porotherm’s modular compatibility with other sustainable systems—recycled insulation, low-E finishes, solar-ready orientations—further enhances its appeal, offering a cohesive solution beyond mere brick replacements.

Looking forward, strategic collaboration between Porotherm’s European heritage and emerging U.S. green building coalitions may accelerate adoption. With climate resilience now central to construction, the bricks’ proven track record in wildfire-prone California, flood-resistant Gulf Coast projects, and temperate Northeast environments positions them as adaptable assets.

Their delayed entry into the U.S. market reflects systemic inertia—but not inferiority. As the industry shifts toward embodied carbon reduction and holistic energy efficiency, Porotherm bricks—long sidelined in American dialogue—emerge not as a curiosity, but a critical component of next-generation sustainable construction.

While not yet standard on U.S. job sites, Porotherm bricks represent more than a construction material—they embody a paradigm shift toward intelligent, low-impact building. For markets ready to embrace innovation beyond familiarity, these German-engineered solutions offer a proven path to durability, efficiency, and environmental rigor, proving that sometimes the most advanced option lies just outside the spotlight.

Related Post

Masjid Noor: A Monumental Beacon of Faith and Community in the Heart of Society

Mazda MX-5 RF: Unveiling the Soul of Speed with the SKYACTIV-G 2.0 Engine

AEW Fight Forever Will Be A Single Release Game Evolve Over Time

Dorothy Jo Gideon Biography Life Death and Cause of Death