Piezoelectric Power: The Invisible Engine Transforming Modern Technology

Piezoelectric Power: The Invisible Engine Transforming Modern Technology

From ultrasonic sensors in industrial robots to energy harvesters powering wearable devices, piezoelectric materials are quietly driving innovation across industries. This advanced technology converts mechanical stress into electrical energy, enabling self-sustaining systems that reduce reliance on batteries and cables. As global demand for energy efficiency surges, piezoelectric systems are emerging not just as a component, but as a paradigm shift—transforming how machines sense, move, and generate power.

At the heart of this revolution lies the piezoelectric effect—the phenomenon where certain crystalline materials generate an electric charge in response to applied mechanical force.

First observed in quartz by Jacques and Pierre Curie in 1880, this principle has evolved from niche laboratory applications into a cornerstone of modern engineering. Today, piezoelectric devices span sensors, actuators, energy harvesters, and even acoustic transducers, each unlocking new capabilities in precision and autonomy.

The Core Mechanism: How Mechanical Stress Becomes Electricity

When a piezoelectric material such as lead zirconate titanate (PZT), quartz, or emerging polymer composites is compressed, stretched, or vibrated, internal atomic lattices shift asymmetrically. This displacement creates a charge separation, establishing a voltage across the material’s surfaces—measurable and usable as electrical energy.

"The beauty of piezoelectricity is its simplicity and immediacy," explains Dr. Elena Vasiliev, a senior materials scientist at the Institute for Advanced Energy Technologies. "Unlike chemical processes in batteries, conversion is direct, silent, and instant, offering unmatched efficiency for dynamic environments."

This effect operates bidirectionally: applied force generates electricity, while an externally applied voltage can induce precise mechanical deformation—making piezoelectric elements dual-purpose tools.

The materials’ performance depends on factors including crystal orientation, temperature stability, and mechanical resilience. Advanced ceramics and nanostructured composites now achieve higher energy conversion rates, broadening deployment possibilities.

Applications Revolutionizing Industry and Daily Life

Piezoelectric technology powers a growing array of applications, each leveraging unique material properties to solve real-world challenges. In healthcare, piezoelectric sensors embedded in diagnostics monitor vital signs with unprecedented sensitivity, detecting minute pressure changes in blood flow or tissue response.

Meanwhile, in consumer electronics, piezoelectric vibration motors provide high-fidelity tactile feedback without bulky speakers or magnet systems. "We’ve replaced traditional buzzers in smartphones with piezoelectric elements that deliver crisp, responsive feedback—smaller, lighter, and significantly more energy-efficient," says James Reed, senior engineer at a leading wearable device manufacturer.

Industrial systems increasingly rely on piezoelectric energy harvesters to power wireless sensor networks. Permanent vibrations in machinery—such as in turbines, pumps, or conveyor belts—convert mechanical kinetic energy into usable electricity, enabling batteries-free monitoring of temperature, vibration, and structural integrity.

This self-powered sensing reduces maintenance, extends asset life, and supports Industry 4.0’s vision of fully autonomous operations. In transportation, piezoelectric roadways embedded with sensor arrays capture energy from wheel vibrations and power streetlights or signage, turning infrastructure into miniature power plants.

Energy Harvesting: Paving the Way for a Battery-Less Future

Among the most transformative applications is energy harvesting—harvesting ambient mechanical energy and converting it into usable electrical power. Piezoelectric harvesters are now integrated into shoe soles to generate electricity from walking, turning footsteps into micro-power for wearable devices.

Similarly, insoles equipped with piezoelectric fibers capture energy from heel strikes, promising to extend battery life in smart shoes or medical monitoring wearables by up to 60%.

In urban environments, piezoelectric tiles installed in high-traffic areas harvest energy from pedestrian movement, contributing to self-powered smart city infrastructure. "Every step becomes a data point and a power source," notes Dr. Lena Wang, a researcher at the National Renewable Energy Laboratory.

"The scalability is immense—when combined with efficient storage systems, piezoelectric harvesting could reduce city-wide energy consumption for lighting and signage by meaningful fractions."

Emerging hybrid systems combine piezoelectric materials with solar or thermal harvesters, creating multi-source energy platforms that maximize uptime and efficiency. Even small-scale devices benefit: medical implants powered by piezoelectric generators, using subtle body movements to eliminate periodic battery replacements—a critical advancement in patient safety and device longevity.

Material Innovations Driving Performance and Sustainability

The evolution of piezoelectric technology is closely tied to materials science breakthroughs. While traditional inorganic ceramics like PZT deliver high efficiency, their lead content raises environmental concerns.

The shift toward lead-free alternatives—including potassium sodium niobate (KNN), barium titanate, and biopolymers like polyvinylidene fluoride (PVDF)—addresses toxicity while advancing performance. "Modern composites merge flexibility with power density, enabling piezoelectric films for bendable electronics or fabric-integrated sensors," explains Dr. Vasiliev.

"These materials are strong, durable, and increasingly eco-friendly."

Nanotechnology further enhances functionality. Nanostructured piezoelectric fibers and crystals maximize surface area and responsiveness, improving energy conversion in low-vibration environments. Researchers are even exploring self-healing piezoelectric materials capable of recovering electrical output after micro-damage, extending device life cycles and reducing waste.

Challenges and the Road Ahead

Despite compelling advantages, challenges persist.

Piezoelectric output remains inherently low in ambient conditions, requiring optimized device design and efficient power management circuits. Material brittleness in ceramics limits durability in flexible applications, though polymer-based systems offer improved resilience but with trade-offs in voltage output. Scalability and cost-effective manufacturing of next-gen materials also pose hurdles.

Yet progress is steady.

Standardization efforts, enhanced material processing techniques, and growing investment in piezoelectric R&D signal a maturing industry. From smart homes to autonomous vehicles, the technology is no longer a niche niche—it’s embedded infrastructure in the evolving digital landscape. "Piezoelectric energy conversion is not just an incremental upgrade; it’s a paradigm shift toward sustainable, self-powered systems," states Dr.

Wang. "As we finalize the current generation of devices, the next wave—driven by materials innovation and system-level integration—will redefine what’s possible."

The Future: Piezoelectric Hybrids and System Integration

Looking ahead, the fusion of piezoelectric materials with wireless communication, AI-driven energy management, and 5G connectivity will amplify performance. Piezoelectric micro-grids, capable of aggregating and routing harvested energy in real time, could power distributed sensor networks across entire cities.

Smart textiles woven with piezoelectric threads may harvest energy from body motion while transmitting health data seamlessly—blurring the line between fabric and functionality.

Material scientists continue to push boundaries. Emerging concepts include bio-integrated piezoelectric devices that harvest energy from heartbeat vibrations or muscle contractions for implantable sensors. Such innovations promise not only efficiency gains but profound improvements in quality of life for patients and users alike.

Integration with synthetic biology and self-healing materials may soon enable piezoelectric systems that autonomously repair wear and degrade safely, minimizing e-waste. The vision extends beyond individual devices to interconnected, adaptive environments—responsive cities, intelligent homes, and resilient infrastructure—all powered in part by the silent, steady pulse of piezoelectric energy conversion.

Piezoelectric technology stands at the crossroads of energy efficiency, autonomy, and sustainability. Its evolution from a scientific curiosity to a cornerstone of modern engineering exemplifies how fundamental physics, when applied with precision and purpose, drives real-world transformation.

As global infrastructure adapts to meet climate goals and digital demands, piezoelectric systems are poised to become not just a component, but a defining element of a smarter, cleaner, and more self-sustaining future.

Related Post

Impact Wrestling Records Its Lowest Overall Viewership of 2023 Leading Up to Bound for Glory

Unveiling Joyner Lucas’s Ethnicity: A Journey Of Discovery

Know Exactly When to Act: Master Time Zones with Pst Zone Time Now

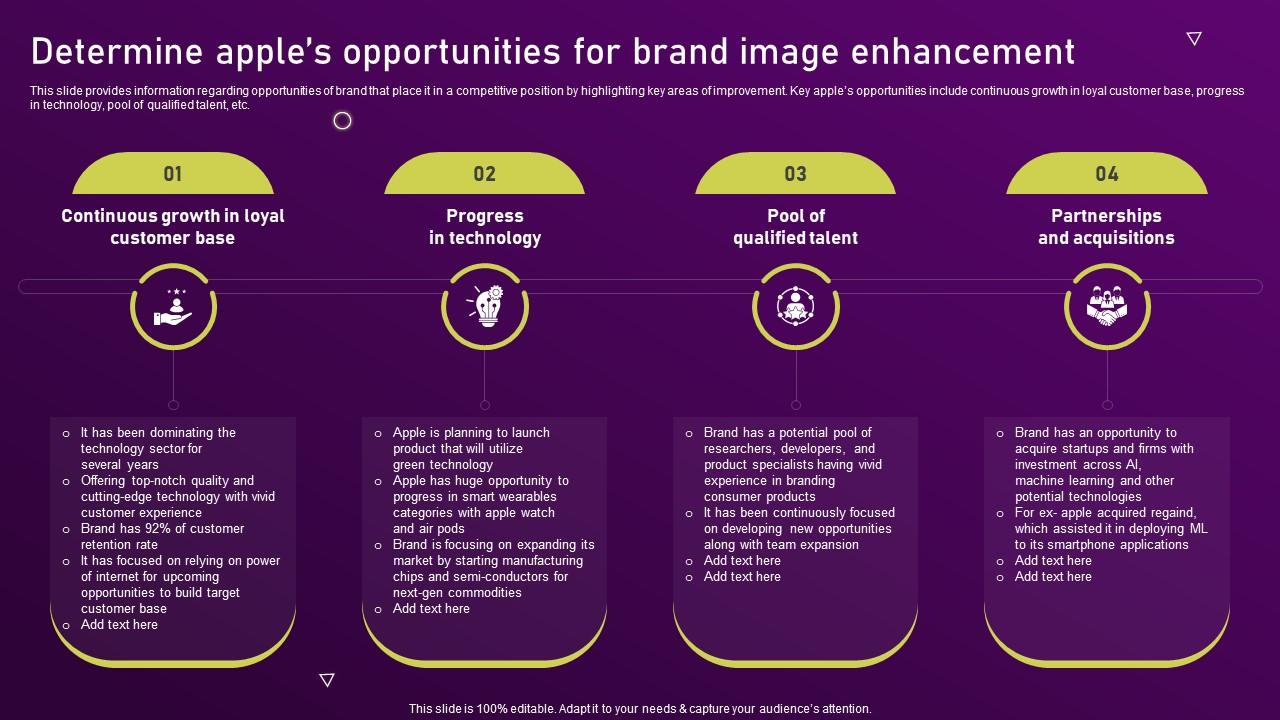

Apples’ Billion-Dollar Empire: Unveiling the Macroeconomics Behind Its Billion-Dollar Net Worth