Netherlands Wind Farm Fire: What Happened in Devastating Blaze?

Netherlands Wind Farm Fire: What Happened in Devastating Blaze?

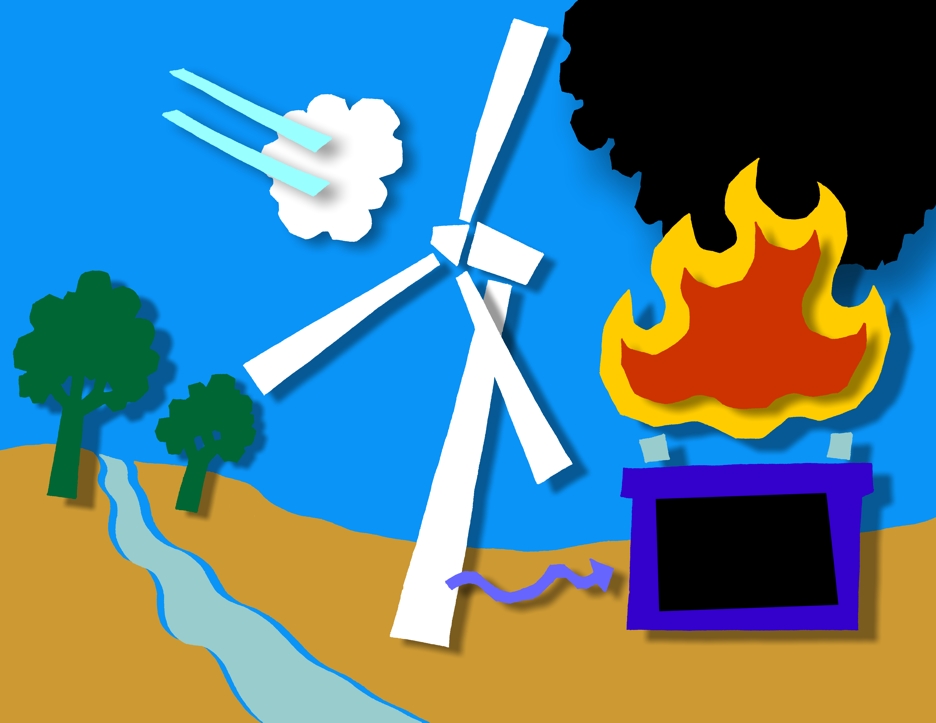

In a harrowing incident that shook renewable energy infrastructure in the Netherlands, a major fire engulfed one of the country’s strategic wind farms in late 2023, exposing vulnerabilities in coastal wind operations and igniting urgent debates over safety, maintenance, and resilience. The blaze, which erupted on a cold November night, rapidly consumed a 150-meter-tall turbine and damaged adjacent facilities, prompting emergency crews and raising critical questions about how such high-altitude industrial accidents unfold—and what can prevent them. What began as a routine night turned into a complex emergency requiring state-of-the-art firefighting tactics and a thorough forensic investigation.

Located along the North Sea coast, the wind farm—part of the Netherlands’ growing offshore infrastructure—was experiencing peak wind generation during the incident.

Eyewitness accounts describe flares erupting from the turbine’s nacelle within minutes of the start, followed by thick plumes of black smoke visible across multiple coastal towns. The fire spread quickly due to a combination of high wind speeds and flammable composite materials used in modern turbine blades. Emergency services arrived within 12 minutes, but the remote installation site posing challenges for access and water delivery prolonged suppression efforts.

The Timeline of Fire Outbreak and Initial Response

The sequence of events, reconstructed from police and utility reports, began at approximately 22:47 local time when sensors detected abnormal heat signatures in Turbine 7.

Initial attempts to remotely activate fire suppression systems failed, forcing crews to deploy specialized fire-fighting drones and water-delivery vessels. “We encountered immediate challenges—high winds hindered landing hurdles, and the compound’s design slowed access to the core fire zone,” said Rob de Vries, operational manager for the grid operator. Firefighters used a mix of water cannons mounted on offshore support vessels and spray drones to combat flames, while specialized teams cordoned off the area.

Despite rapid mobilization, containment was not achieved until over 4 hours after ignition.

By dawn, the fire had consumed the turbine’s rotor and primary structural components. The facility’s control systems were disabled, halting power feed to 3,200 local households and impacting regional grid stability. “The incident exposed how extreme weather can turn routine operations into urgent crises,” noted Jeroen van den Broek, Netherlands’ Energy Safety Commissioner.

“Modern wind farms are exposed to unprecedented environmental stressors—fires like this demand proactive risk modeling and fail-safe engineering.”

Forensic Findings and Primary Causes

An official investigation by the Technical Investigation Bureau (TIB) concluded that a short-circuit in the turbine’s electrical converter system ignited the blaze. The converter—critical for transforming mechanical input into grid-compatible electricity—had exhibited overheating symptoms in the days prior, traced to flawed insulation materials resistant to prolonged thermal stress. Combine with dust accumulation from North Sea salt spray, which accelerated electrical arcing, the conditions created a perfect storm.

The Bruno Le-Marié composite blade, upgraded for efficiency, proved brittle under high heat, fracturing and exposing live conductors.

Further analysis revealed systemic gaps: preventive maintenance schedules had not accounted for environmental degradation rates specific to coastal operations. “Standard protocols were based on inland installations, not the corrosive, humid, high-wind environments here,” explained Dr. Anke Lammers, a fire safety engineer at Delft University of Technology.

“Turbines face not just mechanical wear but accelerated material fatigue—this incident underscores that toughness under stress must be engineered in.”

Aftermath and Regulatory Reforms

In response, the Dutch government launched a comprehensive review of wind farm safety standards. Legislative updates now mandate quarterly thermal integrity testing, use of self-healing composite materials, and enhanced fire detection systems integrating real-time environmental sensors. The Netherlands Wind Energy Association (NWEA) welcomed reforms but stressed industry cooperation: “Adopting new tech and rigorous field testing is essential, not optional, for safeguarding our clean energy transition.”

Financially, the damage exceeded €18 million, covering turbine replacement, grid repairs, and insurance claims.

The fire faltered public confidence temporarily, but officials note that thorough decommissioning of the site and transparent reporting helped restore trust. Safety advocates point to this incident as a turning point—a wake-up call urging other European nations hosting offshore renewables to audit their own systems before another crisis strikes.

Broader Implications for Renewable Energy Resilience

The Netherlands wind farm fire stands as a sobering example of the hidden risks facing renewable infrastructure amid climate volatility. As nations accelerate decarbonization through massive wind and solar deployments, operational vulnerabilities grow more complex.

Lessons from this disaster—rapid response coordination, climate-adaptive design, and predictive maintenance—offer blueprints for resilience. For the future of clean energy, investing in adaptive safety protocols isn’t just prudent; it’s imperative to maintaining public trust and progress. This event is not a defeat, but a catalyst: a moment when crisis spurred clarity, pushing the wind energy sector toward safer, smarter, and more enduring designs.

Related Post

Seohyun & Go Kyung Pyo: The Unstoppable Chemistry That Defined Modern K-Drama Romance

IGood Insurance in Dubai: Your Complete Guide to Navigating Coverage with Confidence

Vice President For JFK: The Power Behind the Presidency