Mastering Reliability: The Mf231 Wiring Harness in Modern Electrical Systems

Mastering Reliability: The Mf231 Wiring Harness in Modern Electrical Systems

The Mf231 Wiring Harness stands as a cornerstone in modern electrical and electronic system integration, delivering robust, organized power distribution with unmatched precision. Engineered for high-performance applications across automotive, industrial, and aerospace sectors, this harness is more than a cable assembly—it’s a precision-engineered solution that ensures electrical integrity under demanding conditions. As demand grows for systems that operate reliably under voltage fluctuations, extreme temperatures, and mechanical stress, the Mf231 harness delivers consistent performance without compromise.

Designed with modularity and scalability in mind, the Mf231 wiring harness integrates multiple conductors, connectors, and protective tubing into a single, cohesive unit. This consolidation minimizes installation complexity while enhancing safety and compliance. Every component is selected to meet stringent industry standards, ensuring compatibility with both OEM specifications and evolutionary technological upgrades.

The Design Philosophy: Performance Meets Durability

At its core, the Mf231 harness embodies a design philosophy centered on resilience and adaptability. Its wiring architecture is built to accommodate signal transmission, power delivery, and data communication within a single, weatherproof enclosure. Specialized insulation materials, such as silicone-based jackets and abrasion-resistant outer sleeves, protect internal conductors from environmental hazards including moisture, UV exposure, and chemical degradation.This proactive defense against wear extends service life and reduces maintenance frequency—critical factors in mission-critical systems.

Key Components and Configurations

A typical Mf231 harness features a configurable wiring topology optimized for specific application requirements. Common configurations include: - A 4- to 16-conductor arrangement, varying by wire gauge and voltage rating - Dual-channel power and signal routing for integrated control systems - Shielded data lines nested within heavily shielded power tracks to minimize electromagnetic interference - Pre-assembled harnesses with lockable crimp connectors for rapid deployment Each unit undergoes rigorous testing, including vibration analysis, thermal cycling, and continuity checks, to validate performance.This ensures seamless plug-and-play functionality across diverse environments—from high-vibration engine compartments to aircraft avionics bays.

Application Distinctions and Industry Impact

In the automotive sector, the Mf231 harness supports advanced driver-assistance systems (ADAS), electric powertrains, and in-vehicle networking, where precision wiring directly influences vehicle safety and autonomy. For industrial machinery, it enables reliable control of motors, sensors, and automation platforms, reducing downtime through fault-tolerant design.Aerospace applications demand extreme reliability under temperature extremes and high-altitude pressure shifts, where Mf231 harnesses meet military-grade MIL-STD-810 and SAE AS60205-1 benchmarks. The adaptability of the Mf231 model allows engineers to tailor harness layouts without sacrificing interoperability, making it a preferred choice for modular system designs.

Why the Mf231 Harness Outperforms Alternatives

Compared to generic or off-the-shelf wiring harnesses, the Mf231 design offers distinct advantages: - Precision-engineered routing that reduces signal loss and electrical resistance - Standardized connector interfaces that streamline installation and reduce errors - Dedicated thermal management features preventing overheating in high-density layouts - Compliance with global certification frameworks enabling seamless regulatory approval “With the Mf231, engineers no longer settle for mid-tier solutions,” says Dr.Elena Torres, Director of Electrical Systems at TechDrive Innovations. “It’s engineered to perform under stress—whether cycling through -40°C to 125°C temperatures or enduring constant flex in dynamic environments.” This engineering rigor has positioned the Mf231 as a benchmark for dur mixed性价比 (value-for-performance) wiring harnesses.

Installation and Maintenance Best Practices

Proper deployment of the Mf231 harness is critical to unlocking its full potential.Technicians prioritize route planning that avoids sharp bends, high-tension zones, and exposure to mechanical abrasion. Connector end-face checks are mandatory, with torque specifications strictly followed to prevent premature bonding failure. Routine inspections focus on connector retention, insulation integrity, and surface cleaning to avoid corrosion—especially in coastal or industrial zones with elevated salt or chemical concentrations.

Routine preventative maintenance, including insulation resistance testing, ensures early detection of degradation, extending harness life beyond projected service cycles.

The Future of the Mf231: Evolution Through Innovation

As smart systems and electrification accelerate across sectors, the Mf231 harness evolves to integrate emerging technologies. Recent iterations feature built-in fiber optic pathways for high-speed data, smart sensor integration for real-time diagnostics, and compatibility with emerging high-voltage vehicle platforms.These advancements position the Mf231 not merely as a wiring solution, but as a foundational layer in next-generation connected systems.

Only harnesses engineered with precision, tested under real-world conditions, and designed for scalability ensure uninterrupted performance in an era defined by complexity and reliability demands. The Mf231 Wiring Harness exemplifies this evolution—transforming electrical connectivity from a basic utility into a robust, intelligent backbone for modern technology.

Related Post

Charley Pride’s Songs: The Soulful Voice That Redefined Country Music

Onion Cell Mitosis: The Molecular Blueprint Behind Plant Growth and Regeneration

Quaresma Ricardo: The Voiced Architect of Resilience in Brazilian Crisis Management

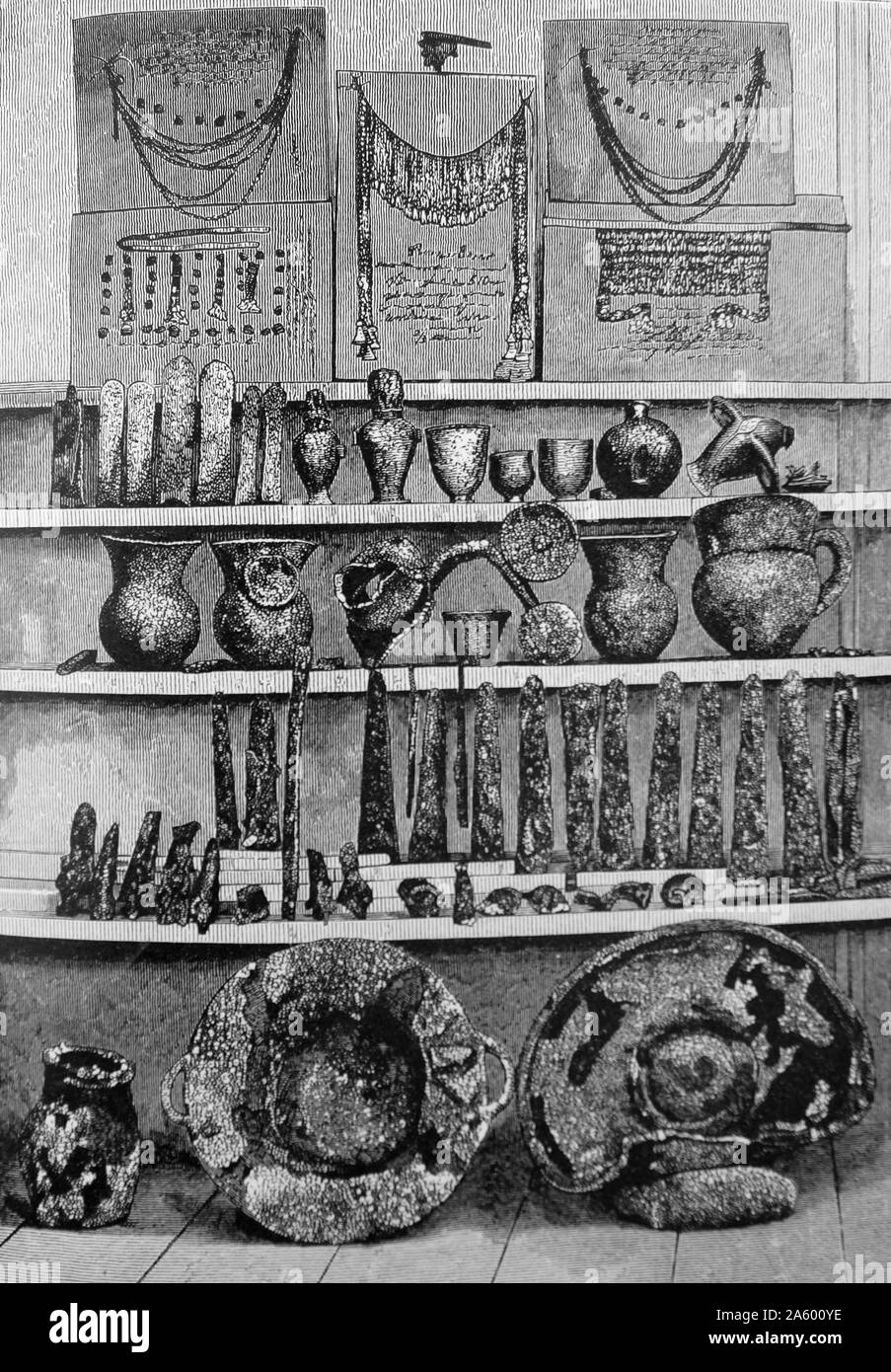

Delving into Schliemann’s Treasure: How a Reluctant Treasure Hunter Reshaped the Tale of Troy