Mastering R410A Pressure Dynamics: High vs Low Side Gauges Explained

Mastering R410A Pressure Dynamics: High vs Low Side Gauges Explained

Understanding the pressure behavior of R410A—a widely used refrigerant in residential and commercial cooling systems—relies on analyzing both high and low-side readings. The R410A Pressure Chart High and Low Side serves as a critical diagnostic tool, revealing vital insights into system efficiency, safety, and performance. Pressures deviate under normal conditions, and interpreting them accurately separates optimal operation from potential failure.

This article dives deep into the significance of high and low-side pressures, decodes their roles in refrigeration cycles, and provides actionable guidance backed by real-world data—all visualized through the foundational reference of the R410A pressure chart. ### The Role of High and Low-Side Pressures in R410A Systems In R410A refrigeration systems, two primary pressure measurement points define system behavior: the high side (condensing pressure) and low side (evaporating pressure). The high side reflects conditions at the compressor outlet, where refrigerant releases heat and transitions from vapor to liquid.

The low side captures pressure at the evaporator exit, indicating how effectively heat is absorbed from indoor air. **Proper pressure ranges depend on load, ambient temperature, and refrigerant charge**, making chart reference indispensable. - **Low-Side Pressure** typically ranges under 25 psig (pounds per square inch absolute) during normal cooling, though extremes vary with ambient conditions.

- **High-Side Pressure** generally exceeds 100 psig under typical operation but can spike significantly under overload conditions. Mismanagement of either side—whether over-pressurizing the high side or under-charging the low side—can lead to premature component failure, reduced efficiency, or even system shutdown. The R410A pressure chart provides a visual and numerical baseline, enabling technicians to compare actual readings against recommended thresholds.

High-Side Pressure: Indicators, Risks, and Chart Benchmarks

High-side pressure readings correlate directly with condensing temperatures and compressor stress. Elevated readings demand attention, signaling potential choke restrictions, suboptimal superheat, or refrigerant charge issues. - **Normal high side pressure**: 100 to 130 psig at standard pressures (e.g., 30°F evaporator temp), though this varies by indoor load and ambient conditions.- **Below normal**: May indicate overcharge (excess refrigerant causing flooding) or restricted condenser airflow, leading to retained heat and poor heat rejection. - **Above normal**: Commonly caused by improper charge, suction line icing, ambient heat gain, or condenser blockage, pushing temperatures beyond safe limits (often exceeding 150 psig can risk compressor damage). According to HVAC industry standards, a high-side pressure above 140 psig at standard suction and condensing temperatures warrants immediate diagnostic review.

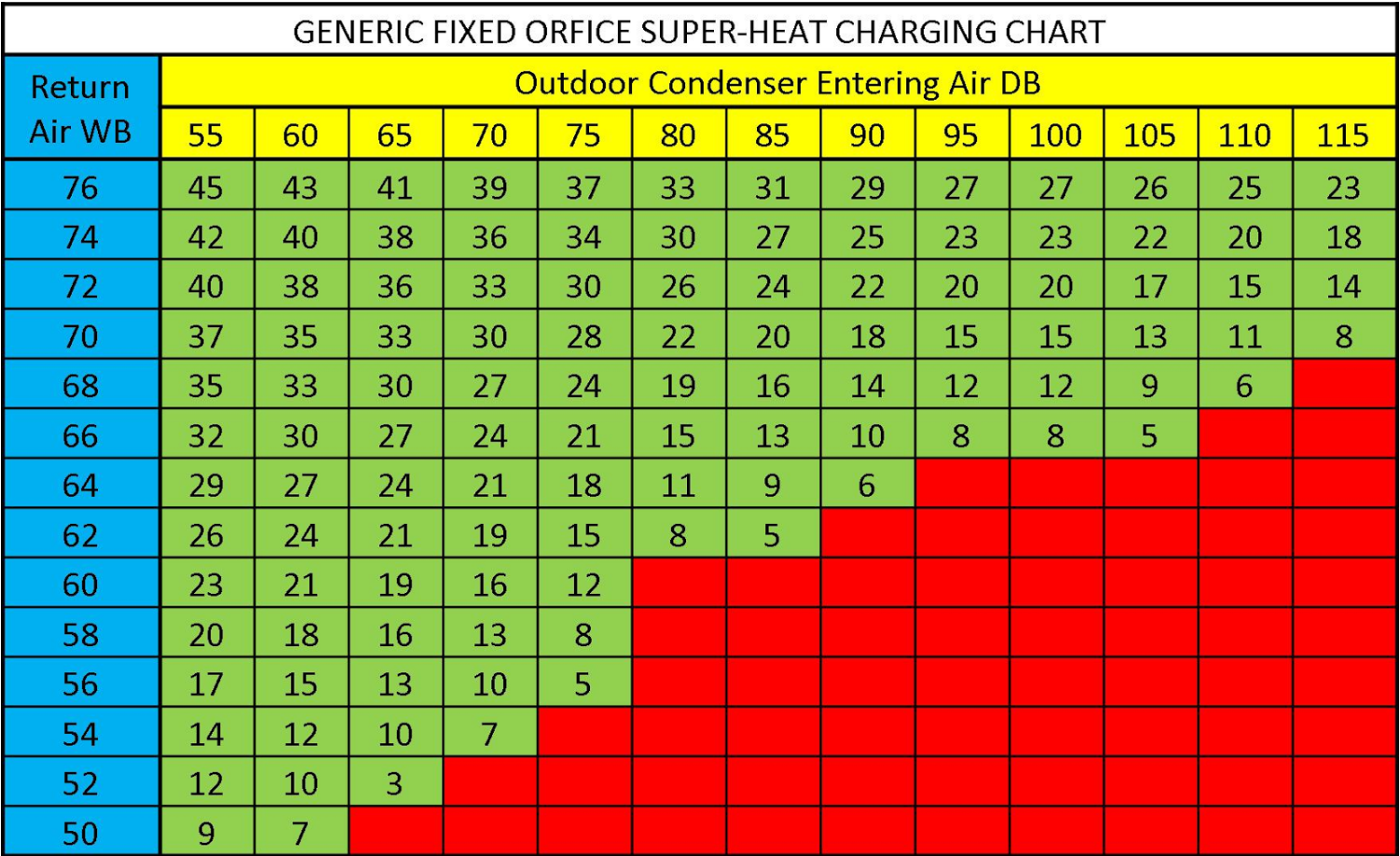

The R410A pressure chart clarifies that as outside temperatures rise, so does the apparent high-side pressure—yet sustained readings above design limits expose risk. *"Excessive high-side pressure often masks root causes—restricted airflow or charge errors—rather than a simple surplus,"* notes certified HVAC technician Raj Patel. “A blanket 20 psig increase above design norms, for example, doesn’t always mean more refrigerant; undercharged systems under extreme heat can show similarly inflated pressure due to poor heat transfer.” Use the chart to identify virtual superheat: ideally, high-side pressure correlates with ~1.8 to 2.0 bar rise per 10°F evaporator superheat.

Deviations warn of under- or overcharging, with high-side pressure climbing rapidly if superheat drops below 2.5–3.0 bar.

Low-Side Pressure: Thriving Efficiency vs Cascading Failures

Low-side pressure reflects evaporator performance, governing cooling capacity and calling attention to refrigerant flow and heat absorption. Maintaining optimal low-side pressure is essential for efficiency and compressor protection.- **Normal low-side pressure**: 15 to 25 psig at standard conditions, aligning with moderate to heavy cooling loads. - **Below normal**: Indicates undercharge, low ambient temperatures reducing thermal demand, or refrigerant distribution issues—potentially leading to insufficient cooling output. - **Above normal**: Often results from overcharge, air obstruction, or a malfunctioning a micrometer restricting flow, increasing compressor workload and risking flooding and liquid slugging.

The R410A pressure chart emphasizes that low-side pressures below 10 psig signal risk of compressor starvation, while values exceeding 35 psig signal significant inefficiency. **A pressure deviation of 10 psig or more from the design sweet spot often triggers performance complaints and higher energy use**. Real-world example: On a 70°F summer day with average indoor cooling needs, a low-side reading near 22 psig indicates proper mass flow and evaporator function.

A drop below 16 psig may stem from improper refrigerant charge, reducing liquid sweep and starving off-design compression—raising risk of compressor damage during sustained operation. *“The low side is often the first advocate of efficiency,”* says equipment engineer Mia Tran. “A slightly elevated low-side pressure—say 30 psig instead of 25—can boost cooling output by 5–8%, yet sustained spikes above 40 psig risk decimating compressor life.

The chart shows exactly where that threshold lies.” Potential root causes include: - Minor charge errors exceeding 5–10% of designed charge - Blocked or frozen evaporators due to frost or dirt - Ambient heat intrusion into air handler plenums - Worn or misaligned metering devices Understanding these triggers, paired with chart-guided comparisons, empowers technicians to restore balance swiftly.

Analyzing the R410A Pressure Chart: High vs Low Side Patterns

The R410A pressure chart integrates both sides, illustrating their functional relationship within the refrigeration cycle. By aligning high and low-side pressures at a given load and ambient condition, the chart reveals whether the system operates naturally or strained.- **Design equilibrium** occurs when high-side pressure is roughly 4–5 times the low-side value (e.g., 120 psig / 25 psig ≈ 4.8), though exact ratios depend on system configuration and charge. - **Abnormal gaps**—such as high-side pressure below low-side readings—signal internal leaks, wrong refrigerant type, or faulty instrumentation. In such cases, the high side drops unexpectedly despite adequate evaporator function.

- **Thermal deviation signs** appear as pressure pressures inconsistent with load: low-side pressures exceeding 30 psig under light load suggest undersizing or insulation loss. High-side pressures rising far above design trends with modest temperature gains signal latent restrictions or superheat mishandling. Table 1 below summarizes typical operating ranges across varying conditions (ambient 50–90°F, normal load): | Parameter | Low Side (psig) | High Side (psig) | Normal Range (psig) | |---------------------|------------------------|-----------------------|------------------------------| | Light Cooling | 15–20 | 100–120 | 15–30 | | Design Load | 20–25 | 110–130 | 20–35 | | Heavy Cooling | 25–30 | 140–160 | 30–45 | | Extreme Heat (85°F+) | 20–28 | 160–180+ | ≤150 (avoid exceed 170) | Source: *ASHRAE Handbook — Application Guide for Refrigeration Systems* These benchmarks emphasize that no single reading tells the full story—context with load and temp is vital.

Practical Steps for System Diagnostics Using the Pressure Chart

Advanced technicians apply the R410A pressure chart not just as a compass but as a diagnostic toolkit: 1. **Benchmark under and oversize conditions**: Compare actual readings to the chart’s load-specific curves to assess charge accuracy. 2.**Track trend analysis**: Record high and low sides hourly during peak loads to detect slow pressure drift indicating gradual leaks or charge loss. 3. **Cross-check with temperature**: Use the chart to link pressure values to dry bulb/wet bulb temps—discrepancies expose charge or airflow issues.

4. **Verify subcooling and superheat**: The chart helps calculate required subcooling at condenser exit and target superheat at evaporator exit, both critical for efficiency. 5.

**Validate safety margins**: Maintain 20–30% safety buffer on the high side and check low-side pressure stays below 40 psig during startup to prevent compressor risk. “Each system has unique fingerprints,” says maintenance specialist Omar Farooq. “The R410A pressure chart turns ambiguous highs and lows into actionable data—helping pinpoint whether the problem is vacuum, charge error, or refrigerant flooding before breakdown.” Example workflow: - Evaporator temp high: 42°F - Low-side pressure: 22 psig - Chart reading: normal combining high of 104 psig and low of 22 psig → 104 / 22 ≈ 4.7, aligning with design - But if high-side later climbs to 160 psig with <25 psig at condenser exit, superheat should exceed 3.5 bar—but here, low-side remains high, pointing to a constriction downstream, possibly an indoor restriction or meter valve stuck closed.

This real-time interpretation prevents costly downtime and ensures optimal performance.

Instructional Takeaways for Technicians and Users

For HVAC professionals and system owners, mastering the R410A high and low side pressure interpretation unlocks proactive maintenance and failure prevention: - **Use the chart as a daily diagnostic anchor**—compare field pressures immediately with reference ranges, adjusting for ambient variances. - **Invest in precision instruments**—digital manometers or built-in BMS sensors ensure readings are reliable, minimizing misdiagnosis.- **Record data in patterns**, noting deviations beyond ±5% from design norms to build predictive maintenance plans. - **Educate staff on pressure wave dynamics**—understanding how charge, superheat, and ambient conditions interact builds a more responsive team. - **Act swiftly on anomalies**—a persistent low-side dip under normal load or high-side surge above 150 psig demands immediate investigation, often before visible symptoms appear.

The R410A pressure chart transforms abstract gauges into diagnostic precision, bridging theory and practice in cooling system optimization.

The Critical Balance: A Systems Approach

The R410A Pressure Chart High and Low Side is more than a datum—it is a gateway to system health, efficiency, and longevity. High and low-side pressures, when read in harmony, expose hidden inefficiencies, forecast failures, and validate charge accuracy.This structured yet dynamic reference empowers technicians and engineers to maintain refrigeration systems with confidence, translating mechanical principles into real-world performance gains. In an industry where even small deviations impact energy use and equipment life, the pressure chart remains an indispensable litmus test. R410A does not just cool air—it reveals diagnostics, demands precision, and rewards informed care.

With the right interpretation, R410A systems operate not just safely, but at peak potential.

Related Post

Iiyama G-Master G2530HSU: A Professional Workstation Powerhouse That Delivers Precision and Performance

Unlocking Regulation Cpa Exam 105174: The Insider’s Guide to Mastering CPA Candidates’ Most Challenging Topic

Knoxville Rocks: When the Earth Shakes Beneath Tennessee’s Cultural Heart

Inside Ashley Biden’s Diary: Unfiltered Insights Into A Life Beyond the Spotlight