Master the Essentials: Ec601 Control System & Instrumentation Deep Dive Based on Makaut Question Paper

Master the Essentials: Ec601 Control System & Instrumentation Deep Dive Based on Makaut Question Paper

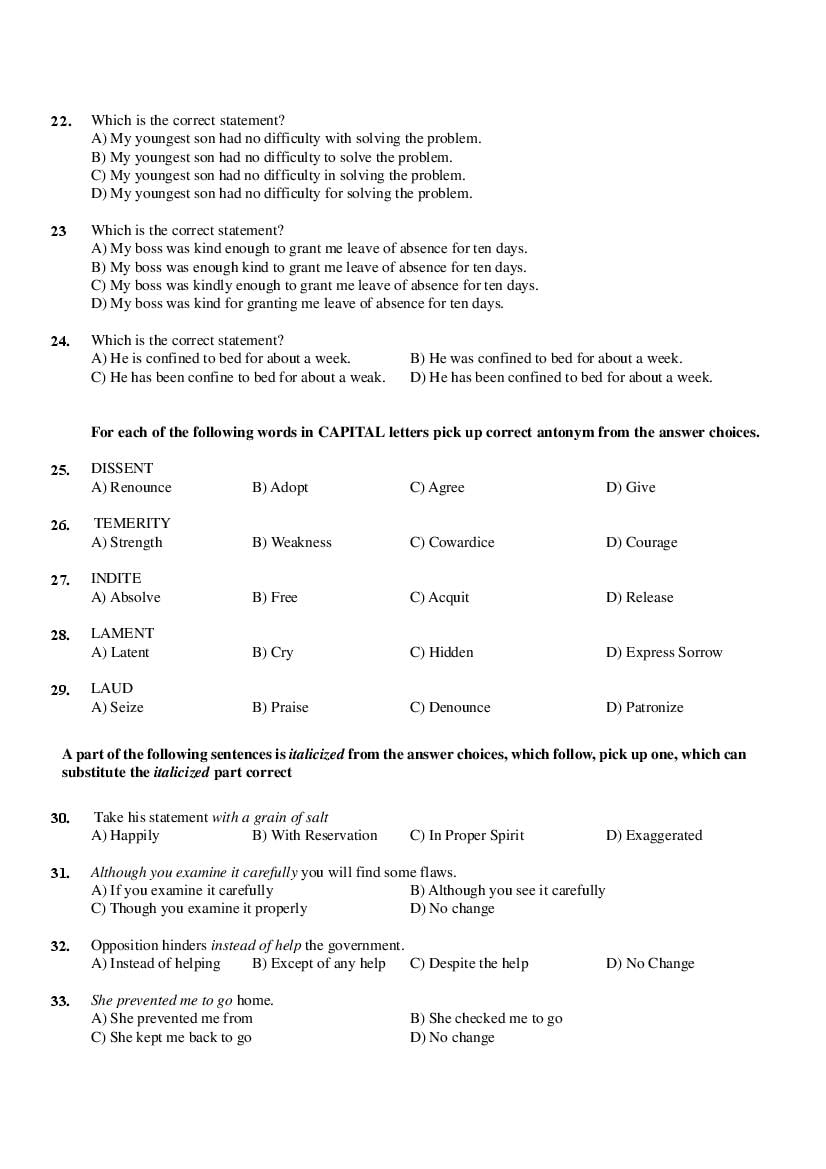

In an era where automation shapes industrial efficiency, grasping the core principles of control systems and instrumentation is no longer optional—it's foundational. The Ec601 Control System and Instrumentation Question Paper from Makaut delivers a comprehensive litmus test, probing candidates’ understanding of core concepts, practical applications, and analytical problem-solving in process control. This article unpacks the key themes and technical demands revealed through the paper, equipping engineering students and professionals with targeted insights to excel.

Core Components & Instrumentation Fundamentals

At the heart of control system theory lies instrumentation—enabling measurement, monitoring, and feedback in dynamic processes. The Makaut question paper consistently emphasizes instruments like transmitters, sensors, and actuators, underscoring their critical role in translating physical parameters (temperature, pressure, flow) into actionable electrical signals. - Devices such as RTDs (Resistance Temperature Detectors), pressure transducers, and flow meters are analyzed not just for proper operation, but for integration into loop configurations like PID control.- Signal conditioning—amplification, filtering, analog-to-digital conversion—is repeatedly tested, reflecting its importance in reducing noise and enhancing data fidelity. “Accurate instrumentation forms the sensory nervous system of any control loop,” as emphasized in the paper’s technician perspective, revealing that measurement integrity directly impacts system stability and performance.

Control Loop Dynamics and Feedback Mechanisms

Feedback control lies at the technical core of automation, and the question paper rigorously examines closed-loop systems.Candidates must analyze transfer functions, adjust loop gains, and troubleshoot instability—skills essential for real-world process optimization. - Key topics include phase margin, gain margin, and Bode plots, with several sample problems requiring graphical interpretation of system response shapes. - Stabilité—often tested through step response analysis—remains a recurring theme, demanding understanding of time constants, overshoot, and settling time.

“Each loop is a predictive dialogue between model and reality; mastering feedback is mastering control,” a passage from the paper underscores the calculus of intervention and correction. Students face scenarios where modifying controller parameters reveals trade-offs between speed and stability, fostering deeper intuition beyond textbook formulas.

Instrumentation Networks and Communication Protocols

Modern control systems rely on reliable communication between sensors, controllers, and HMIs.The Makaut paper scrutinizes fieldbus architectures, focusing on protocols such as Modbus, HART, and Profibus. - Representing communication as a real-time data highway, questions challenge candidates to map data flow, error detection, and redundancy strategies within industrial networks. - Integration challenges—like signal interference, latency, and protocol translation—are explored through diagnostic troubleshooting exercises.

“Communication isn’t just about bits—it’s about minding topology,” advises one model, emphasizing that network resilience directly safeguards operational continuity. Understanding these protocols ensures engineers design scalable, secure, and interoperable systems, crucial in Industry 4.0 environments.

Safety, Redundancy, and Industrial Standards

In high-hazard industrial settings, reliability transcends performance—it’s a matter of compliance and life safety.The paper stresses adherence to global standards such as IEC 61131 for programmable controllers and IEC 61508 for functional safety. - Redundancy strategies—triple modular voting in safety instrumented systems, dual-powered sensors—are interrogated with emphasis on risk mitigation. - Fault detection, alarm management, and fail-safe logic programming dominate problem-solving segments, reflecting real-world demands.

“Redundancy isn’t an add-on; it’s the baseline protective architecture,” the paper asserts, reinforcing that robust design must anticipate failure, not ignore it.

Data-Driven Optimization and Future Trends

The evolution of control systems is increasingly data-centric, blending classical PID logic with advanced analytics. The Makaut examination reflects this shift by integrating concepts from SCADA, DCS, and early adoption of AI-assisted tuning.- Case studies highlight how predictive maintenance leverages real-time sensor data to preempt failures, reducing downtime. - Digital twins and simulation-based tuning—once niche—now appear in application-based questions, demanding hands-on familiarity. “Live measurements inform models, models predict, and control acts—closing the loop with intelligence,” a sample problem illustrates this convergence, merging theory with the digital edge.

This forward-looking blend ensures graduates are not just competent today, but adaptable to the next wave of industrial transformation.

Through consistent emphasis on instruments as enablers, feedback as strategy, communication as infrastructure, safety as principle, and data as textbook, the Ec601 Control System and Instrumentation Question Paper emerges not just as an exam benchmark, but as a mirror of industry excellence. For aspirants, mastering these focal areas means building a toolkit capable of commanding complex systems with precision, resilience, and innovation.

Related Post

It Takes Two: Unlocking the Science and Soul of Partnership

Matt Egan CNN Bio Wiki Age Height Wife Salary and Net Worth