Ive Members: The Secret Safeguard of Automotive Excellence and Security

Ive Members: The Secret Safeguard of Automotive Excellence and Security

Behind every Ive, the premium electric vehicles heralded as the future of sustainable mobility, lies a network of elite members whose contributions ensure not only technological supremacy but also rigorous safety and security standards. These Ive Members—engineers, designers, cybersecurity specialists, compliance officers, and inspectors—operate with precision, each playing a vital role in safeguarding the brand’s innovation and user trust. From battlefield-grade cybersecurity protocols to elite-grade quality assurance, this elite cadre forms the backbone of Ive’s uncompromising commitment to excellence.

Their collective expertise transforms cutting-edge engineering into matter-of-fact reliability, making each Ive not just a car, but a fortress of innovation.

Central to Ive’s operational elite are the lead engineers—specialists who blend deep mechanical knowledge with software mastery to architect driving systems that redefine performance. “Our team doesn’t just build electric powertrains,” explains Dr.

Elena Torres, Senior Powertrain Engineer at Ive. “We design adaptive energy management that learns from every mile, optimizing efficiency while anticipating real-world stressors.” These engineers operate at the intersection of hardware and intelligence, integrating high-performance motors, proprietary battery systems, and AI-driven driving algorithms. Their designs ensure each Ive delivers responsive acceleration, adaptive regenerative braking, and seamless connectivity—all under extreme conditions.

The precision demands absolute discipline: failure margins are measured in thousandths, not miles.

The human element extends beyond engineering into the realm of security. Ive employs a dedicated cadre of cybersecurity specialists tasked with protecting the vehicle’s increasingly complex digital ecosystem. As the number of connected systems grows—from over-the-air updates to biometric access—so does vulnerability.

“Every firmware line, every wireless command, must pass relentless testing,” says encryption expert Rajiv Mehta, head of Ive’s Cybersecurity Division. “We deploy hardware-backed security modules, mimic real-world attack vectors, and zero in on threats before they reach user vehicles.” By embedding layers of adaptive protection—from secure boot processes to encrypted cloud communication—Ive ensures driver data remains private and vehicle controls remain impervious to intrusion. In an age where vehicles are nodes in a global network, this digital shield is non-negotiable.

Quality assurance forms the third pillar of the Ive Member ecosystem.

A painstaking team of inspectors and testers operates behind closed doors, applying standards sharper than any regulatory checklist. “We don’t just conform—we exceed,” states Marta Lin, Head of Quality Assurance. “Each weld, sensor, and software module undergoes simulated real-world stress: from salt-laden coastal winds to sub-zero mountain roads.

Every anomaly triggers a root-cause analysis, never a workaround.” This relentless scrutiny ensures that from the first test drive to eventual delivery, every Ive is flawless. The team’s manual inspections are complemented by automated diagnostics that scan for micro-defects invisible to the human eye—guaranteeing consistency across production batches.

Complementing the technical prowess is a cross-functional synergy among Ive Members that fuels continuous innovation. Monthly syncs between engineers, designers, and compliance analysts foster rapid iteration, allowing challenges to be solved before they become bottlenecks.

“Our members don’t work in silos—they collaborate as a pulse of excellence,” says Masaki Ishida, Head of Product Innovation. “When a software update reveals a latency issue, our cybersecurity team scours for exploit vectors while our hardware engineers verify physical impacts. This integrated approach means faster fixes, sharper security, and stronger performance.” This culture of dynamic collaboration turns potential risks into growth opportunities, reinforcing Ive’s leadership in both sustainability and safety.

Operational Architecture: The 3-Step Guardian Framework

- Pre-Engineering Safeguarding: Design and simulation labs use predictive modeling to identify failure modes before components are built, reducing later rework.

- Production Integrity Checks: Each vehicle passes a composite of 120+ automated and manual checks, including vibration, thermal, and software validation.

- Post-Deployment Vigilance: Over-the-air monitoring feeds real-world data back to Ive’s central operations, enabling proactive updates and member-driven safety alerts.

Beyond technical routines, Ive Members embody a shared ethos: innovation fused with irrevocable responsibility.

Whether shielding quantum-encrypted user data or certifying brake systems to crash-test perfection, their daily choices shape trust. In the evolving battle between technology advancement and systemic vulnerability, Ive’s members are not just enforcers—they are architects of a safer, smarter transportation future. Their commitment transforms the headline claim of “premium electric innovation” into an operational reality where excellence isn’t aspirational—it’s enforced, validated, and lived.

In an industry where breakneck innovation collides with relentless risk, the true strength of Ive’s vehicles lies not in the battery capacity or motor torque alone, but in the vigilant hand of Ive Members—engineers, guardians, and pioneers who dare to anticipate the unknown.Their collective excellence ensures that each Ive is more than a symbol of sustainable progress: it is a testament to what rigorous, people-driven quality achieves in the rank-and-file of high-stakes engineering.

Related Post

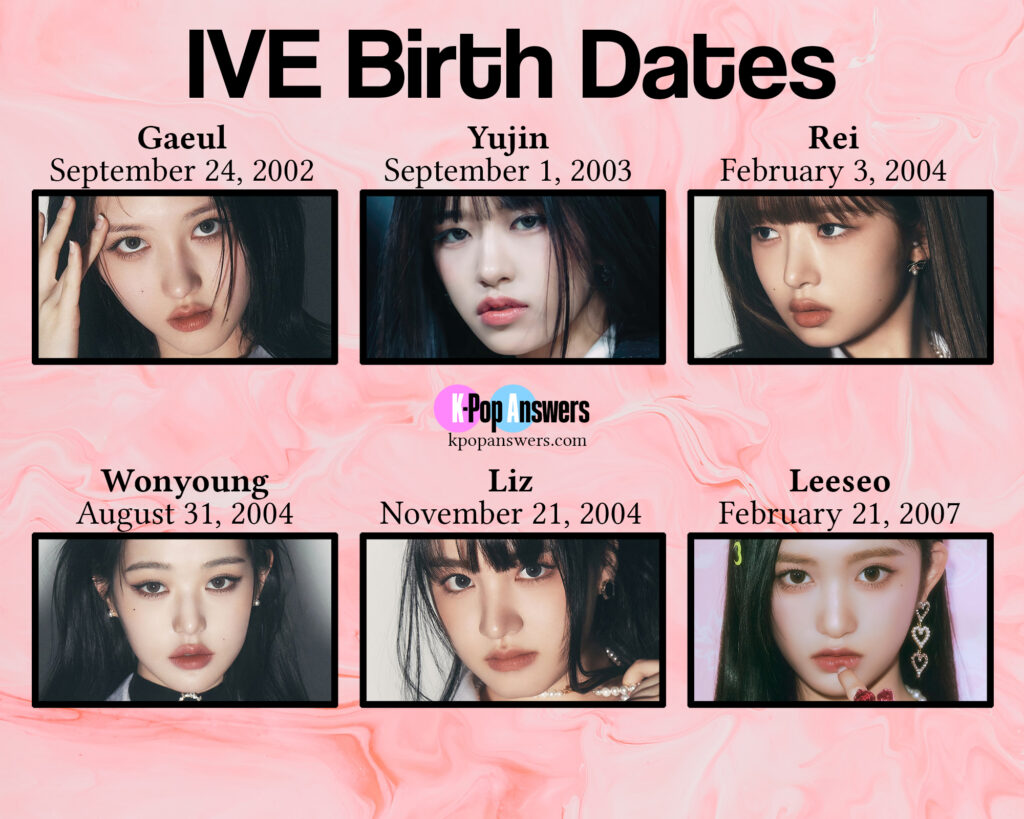

From Generations to Sound: How Ive Members From Oldest to Youngest Forge Legacy

Levels of Lifetime Membership: Unlocking Exclusive Benefits Across Transformative Membership Journeys

OSC Gotham SC: Monthly Sports Costs Breakdown Revealed for Prospective Members