George Stults Redefines Precision Engineering Through Aerospace Innovation

George Stults Redefines Precision Engineering Through Aerospace Innovation

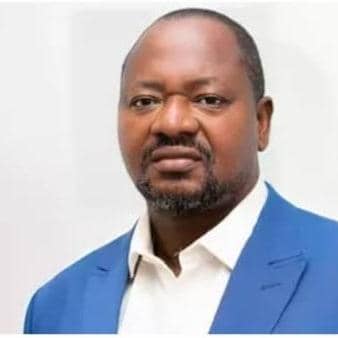

George Stults, a visionary in aerospace engineering, stands at the forefront of advanced structural design, driving breakthroughs that blend computational rigor with real-world performance. His work has not only elevated aircraft and spacecraft structural efficiency but has also set new benchmarks in safety, weight optimization, and durability across complex aerospace systems. großer Einfluss von George Stults Stults’ career is defined by his pioneering application of finite element analysis (FEA), topology optimization, and advanced simulation techniques to solve some of aerospace engineering’s most persistent challenges.

By integrating cutting-edge software tools with deep physical insight, he has transformed how engineers approach load distribution, stress mitigation, and material utilization in flight-critical components. His methodologies reduce structural weight without compromising integrity—reducing fuel consumption and extending mission capabilities. “Precision isn’t just about accuracy—it’s about confidence in every curve, every joint, every layer,” Stults has emphasized, capturing the ethos behind his engineering philosophy.

From fighter jets to orbital vehicles, Stults has contributed to projects that define modern aviation. His expertise lies in leveraging multiscale modeling—from microstructural material behavior to full-scale aerodynamic loading—enabling engineers to anticipate failure points before fabrication. This predictive capability shortens development cycles and minimizes costly redesigns, a critical advantage in competitive aerospace markets.

Key projects under his guidance include structural validation for next-generation unmanned aerial systems (UAS) and next-level thermal protection systems for re-entry vehicles. Through these innovations, Stults has helped bridge the gap between theoretical design and sustainable, high-performance flight.

Core Engineering Principles Driving Innovation

At the heart of Stults’ approach is a relentless focus on integrating analytical rigor with practical constraints.His methodologies emphasize three pillars: - **Multidisciplinary Optimization**: Stults merges aerodynamics, structural mechanics, and thermal dynamics in unified simulation environments, ensuring structural designs operate harmoniously within broader system requirements. - **Advanced Material Integration**: By closely collaborating with material scientists, he optimizes composite layup sequences and additive manufacturing techniques to tailor strength-to-weight ratios. - **Real-Time Validation Protocols**: Employing digital twins and field data feedback, Stults embeds continuous verification, refining models against actual operational loads—ensuring aircraft and spacecraft withstand the rigors of flight.

This holistic framework allows engineers to explore non-intuitive design solutions, pushing performance boundaries while maintaining or improving safety margins.

The Digital Revolution in Aerospace Structural Design

George Stults was among the early adopters and advocates of high-fidelity computational tools that now define the industry. His teams have mastered the use of next-generation FEA platforms, machine learning-enhanced solvers, and parametric design environments to simulate and validate complex load cases.“Simulation used to be an afterthought,” Stults reflects. “Now it’s the compass guiding every rivet installation.”

Key tools and techniques under his leadership include: - Composite Structural Optimization: Using genetic algorithms and gradient-based solvers to determine optimal fiber orientations and stacking sequences. - Multi-Physics Coupling: Integrating thermal expansion, fatigue life, and aerodynamic heating into unified simulation workflows.

- Topology Optimization: Automating material placement to distribute load paths efficiently across lightweight structures, reducing mass by up to 30% without sacrificing rigidity. These innovations are not theoretical. They are implemented daily in aerospace OEMs where Stults’ methodologies are shaping the production lines of tomorrow’s aircraft and spacecraft.

Pioneering Applications Across Aerospace Platforms

One of Stults’ most visible impacts is in the development of advanced UAVs—unmanned systems that demand extreme endurance and reliability. In modern drone platforms designed for extended surveillance and payload delivery, his structural models ensure components endure thousands of flight hours without fatigue failure. “In UAS, every gram matters—and so does every millisecond of mission life,” Stults explains, underscoring the life-or-death precision required.His work extends to crewed aerospace as well.

Related Post

George Stults Bio Wiki Age Height Wife Brother Movies and Net Worth

George Stults: Pioneering Biomechanics, Longevity Insights, and the Legacy of Family in Science

Severe Sepsis: The Silent Killer That Demands Immediate Action

Leading Insights from Perceptive Analyst James Wentzel