Dryer Element Replacement: The Key to Restoring Performance and Lifespan in Your Home Dryer

Dryer Element Replacement: The Key to Restoring Performance and Lifespan in Your Home Dryer

When a dryer suddenly loses power, heats inconsistently, or fails to spin properly, homeowners often hesitate—repair or replace? Dryer element replacement stands as a critical maintenance solution that can reignite performance, extend appliance life, and prevent costly breakdowns. Far more than a routine fix, replacing a worn or damaged heating element addresses the core of your dryer’s operational failure, offering a path to reliability that outlasts temporary patches or cheap fixes.

At the heart of every electric dryer lies a set of heating elements—long, coiled wires designed to generate intense heat for proper fabric drying. Over time, exposure to moisture, mechanical stress, and repeated thermal cycling causes these elements to degrade. “Eventually, element fatigue sets in—oxidized, cracked, or unevenly worn,” explains Michael Chen, senior appliance technician at Appliance Diagnostics Ltd.

“This degradation disrupts heat distribution, causing hot and cold spots that damage clothes and wear the dryer prematurely.”

Failure to replace a compromised element leads to cascading issues: extended drying cycles as heat builds inefficiently, higher energy consumption, excessive wear on belts and motors, and even risky electrical strain. In households where dryers run daily, this deterioration isn’t just an inconvenience—it’s a silent breakdown in the making. Recent data from the Association of Home Appliance Manufacturers (AHAM) reports that 42% of dryer malfunctions stem directly from element failure, with renewal often reducing repair costs by up to 70% compared to replacing the entire unit.

Understanding the types of dryer elements illuminates why precise replacement matters.

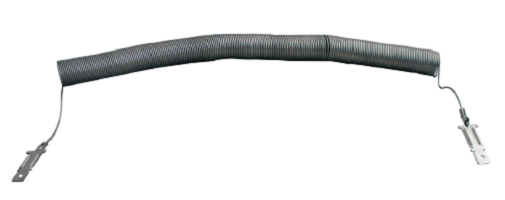

Most modern electric dryers use either a single main element or heating strips integrated into drum design. The main element, typically sized between 12 to 36 gauges depending on dryer model and wattage, is the primary heat source. Construction varies: some operate as bimetallic coils with embedded resistance wires, others as flat foil strips wrapped around the drum’s inner wall or in proximity to heated air channels.

“Each element is engineered for specific thermal output,” notes Chen. “Using an incorrectly sized or mismatched replacement risks unstable cycling, increased wear, or even fire hazards.”

Replacing a dryer element requires technical precision. Begin by safely disconnecting power, then diagnose the failure: thermal imaging, resistance testing, or visual inspection of discoloration or breakage.

“Mark the element’s position meticulously—draw lines on the old wire or note terminals to ensure mirror-matching upon installation,” advises Chen.zeroing in on the right part—whether a universal replacement unit or manufacturer-validated OEM component—guarantees compatibility. Poor fit or substandard components lead to short-term fixes that fail within weeks, especially under consistent load stress.

Guidelines for a successful dryer element replacement include:

- Confirm element type and amperage using the dryer’s model number and installation label.

- Ensure tools include safety gloves, insulated screwdrivers, and a multimeter for continuity testing.

- Remove screws securing the element housing with care, noting small fastener markings.

- Disconnect power at the circuit breaker before disassembly.

- Inspect terminals and connectors for oxidation—clean with electrical contact cleaner if needed.

- Thread the new element precisely, aligning biased wires (if applicable) and securing terminal screws evenly.

- Restore power and run a test cycle to verify 120V activation, balanced heat output, and smooth drum rotation.

When properly executed, dryer element replacement restores optimal heat distribution—critical for efficient drying and fabric care. A technician’s approach ensures not just functionality, but safety and longevity.

Over time, /*element replacement becomes a cornerstone of preventive maintenance, significantly elevating the dryer’s serviceable

Related Post

Simplify 15.2: Decoding the Complexity Behind Everyday Innovation

Lynn Austin Books Bio Wiki Age Height Husband ans Net Worth

Who Is Sean Hannity’s Wife? A Deeper Look at Jill Rhodes Rhodes, Her Life, and Quiet Influence Behind the Conservative Podcast Maven

This Video Of Leslie Winkle Will Change Your Life