Discover How SCM Parts Transform Every Woodworker’s Workshop

Discover How SCM Parts Transform Every Woodworker’s Workshop

In the evolving world of woodworking, precision, durability, and adaptability define success—psych raw materials alone cannot deliver. SCM Parts have emerged as a game-changing solution, offering standardized, interchangeable components engineered for performance, efficiency, and compatibility across tools and projects. By integrating modular fasteners, precision-machined hardware, and engineered assemblies, SCM Parts revolutionize how woodworkers build, replicate, and scale craftsmanship.

This article breaks down the core principles, applications, and benefits of SCM Parts—everything you need to understand why they’re becoming essential in modern woodworking workshops.

What Are SCM Parts and Why Woodworkers Rely on Them

SCM Parts—short for Standardized Component Modules—represent a shift from custom fabrication to factory-engineered, interchangeable hardware and assemblies tailored for woodworking. Unlike traditional off-the-shelf fasteners or one-off hardware, SCM Parts are designed with strict tolerances, consistent materials, and verified compatibility.These components include clamps, brackets, doweling systems, mortise-joint connectors, and tool holders, all built using precision manufacturing techniques. “Single-source SCM Parts eliminate guesswork,” says Michael Tran, master woodworker and SCM certification instructor at Appalachian Craftwork Institute. “A woodworker no longer struggles to match part dimensions or settle for inferior off-brand hardware—every component is verified for fit, strength, and durability.” This standardization greatly reduces setup time, improves repeatability, and ensures structural integrity across projects.

SCM Parts are not just parts—they’re a system designed for woodworking’s demanding conditions, combining engineering rigor with practical convenience to meet both artisan demands and production needs.

Core Elements of SCM Parts for Versatile Woodworking Applications

SCM Parts cover a broad functional spectrum, each engineered to solve common woodworking challenges. Key categories include: - **Jigs and Fixtures**: From table-mountable clamps to router tables with modular guide systems, SCM Jigs ensure consistent alignment and repeatable cuts, reducing human error and boosting workflow efficiency.- **Joinery Hardware**: Precision mortise pegs, dowel connectors, and biscuit-aligned joining modules enable traditional yet engineered wood connections. These parts maintain mechanical strength while allowing for rapid assembly. - **Clamping Systems**: High-tension, self-locking SCM clamps provide secure, vibration-resistant hold with minimal downtime—critical for power tools like lathes or router machines.

- **Tool Accessories**: Universal collets, shaft adapters, and alignment rails integrate seamlessly with a wide range of power tools, streamlining operator changeovers and enhancing machine versatility. - **Safety Modules**: SCM-compliant splitters, moisture control clips, and tool-mounted guards enhance shop safety without sacrificing performance—addressing a persistent, often overlooked need. “The beauty of SCM Parts lies in their ability to blend multiple woodworking disciplines into one coherent system,” explains Elena Rossi, a senior ethnographer specializing in workshop design.

“Whether you’re building custom furniture, producing cabinetry in series, or maintaining historical techniques, a matching SCM ecosystem supports every phase.” This tiered approach to modular hardware means woodworkers—whether hobbyists or small business owners—can standardize inventory, minimize waste, and focus on craftsmanship rather than logistics.

How SCM Parts Enhance Accuracy, Speed, and Consistency

Accuracy in woodworking hinges on reliable interfaces between materials, tools, and assemblies. SCM Parts deliver this through carefully controlled manufacturing that eliminates dimensional variances.Each part is produced to exacting standards, often within ±0.02 mm tolerances, ensuring perfect alignment in mortises, joinery, or multi-component builds. Efficiency gains stem from module compatibility: a single SCM caliper adapter may connect router, table saw, and drill—reducing tool clutter and setup time by up to 40% in production environments. “Imagine not having to check 12 different clamp types for a single project,” notes Ryan Cole, lead technician at Urban WoodWorks.

“SCM Parts turn a chaotic assembly into a linear, predictable process.” Consistency across builds is equally critical. In custom furniture, for instance, matching grain patterns and thread alignment across panels requires holistic precision—achievable only through a coordinated set of SCM components that maintain tight fit-over-fit performance. “Consistency isn’t just about fit—it’s about trust,” says Lisa Moreau, AIA-certified wooddesign expert.

“When every dowel, clamp, and fastener behaves predictably, craftsmanship becomes repeatable, not random.” Moreover, SCM Parts integrate seamlessly with digital tools. Laser-machined referencing symbols, RFID-embedded part trackers, and digital assembly guides now complement physical components—creating a hybrid workflow that merges traditional hands-on skill with smart-tech precision.

Choosing the Right SCM Parts for Your Workshop Size and Style

SCM Parts are engineered for scalability, making them suited to diverse woodworking environments—from solitary studios to lightweight production

Related Post

Freddie Freeman’s Stature and Sprint: How Height Shaped a Pitching Powerhouse

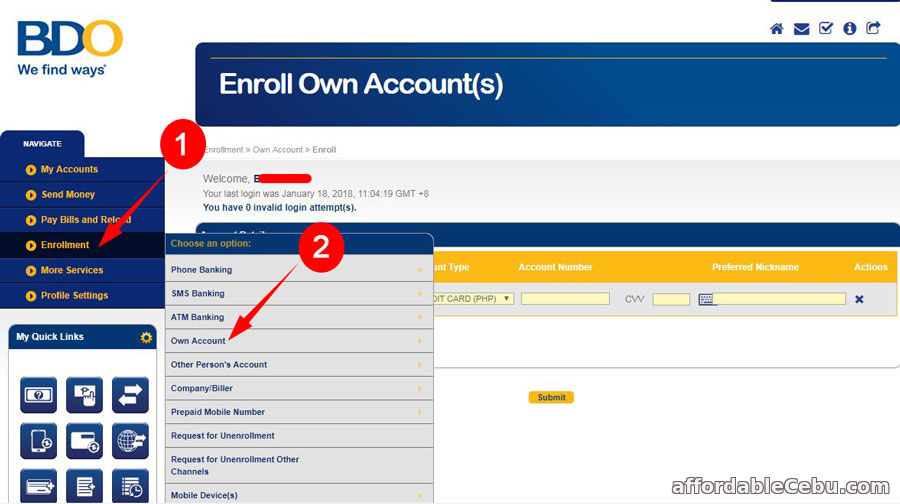

Enroll Bdo Online Banking: Your Step-by-Step Guide to Effortless Digital Banking

The Political Compass Decoded: How Lingering Ideologies Shape Modern Democracy

Insightful Profile Regarding Devon Shae Tits Industry Role