Diesel Oil Viscosity: The Engine’s Lifeline That Demands Precision

Diesel Oil Viscosity: The Engine’s Lifeline That Demands Precision

Understanding diesel oil viscosity is not just a technical detail—it is a cornerstone of engine reliability and longevity. Every drop of lubricant circulating through a diesel engine carries a specific viscosity status, directly influencing friction, heat control, and wear rates. The right viscosity ensures optimal film strength between moving parts, minimizing metal-on-metal contact and safeguarding critical components like bearings, camshafts, and piston rings.

As engine demands rise with higher performance and fuel efficiency goals intensify, so does the necessity to select and monitor the correct viscosity grade with scientific precision. When viscosity is mismatched, the consequences range from accelerated component degradation to catastrophic failures—making this property a vital metric for maintenance professionals and vehicle operators alike. What exactly is diesel oil viscosity, and why does it matter so deeply for engine health?

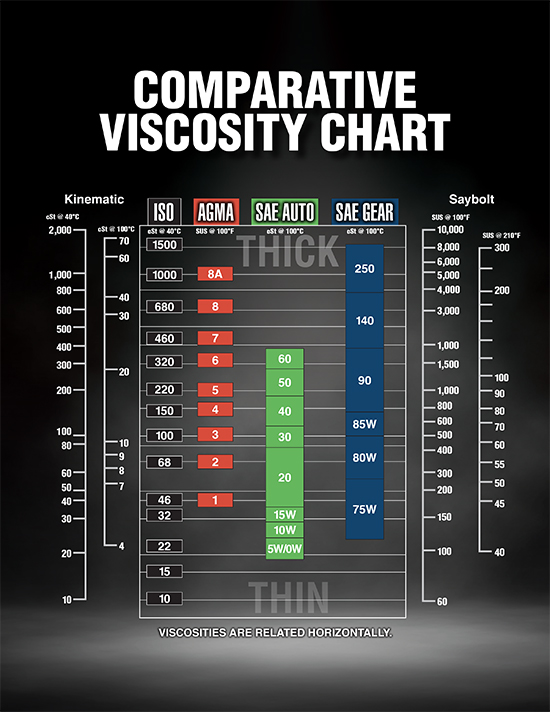

Viscosity, at its core, measures a fluid’s resistance to flow—essentially how “thick” or “thin” diesel oil behaves under operational conditions. In engines, this property governs how effectively lubricant clings to surfaces under pressure, shear stress, and temperature variation. The standardized unit for reporting viscosity, the Stuve or SAE index, reflects performance across expected temperature ranges, with grades like 10W-30 or 15W-40 designed to deliver consistent protection across cold starts and high-compression cycles.

Without the proper viscosity, oil cannot form a stable lubricating film, creating zone of high shear that initiates wear. Professional mechanics and fleet operators emphasize that viscosity is far more than a label—it’s a dynamic protector of engine integrity. Choosing the wrong viscosity can trigger a cascade of problems.

Selecting an oil with insufficient viscosity leads to thin lubricant layers, increasing friction and localized overheating. This accelerates wear in critical areas such as cylinder walls and connecting rods, a well-documented issue highlighted in technical service bulletins. Conversely, using oil too thick—viscosity exceeding recommended limits—impedes flow during cold starts, delaying oil delivery and increasing initial friction as parts resist initial motion.

Both extremes compromise efficiency, raise fuel consumption, and shorten engine life. Engine builders stress that viscosity must align precisely with OEM specifications and operating environments, including ambient temperature, altitude, and duty cycle. Real-world data from diesel fleet analytics confirm that engines running at improper viscosity experience 25–30% faster degradation in bearings and gears compared to those using optimal grades.

The relationship between viscosity, temperature, and engine design is both nuanced and critical. Diesel engines generate extreme heat—under the hood, temps can soar above 100°C during normal operation. To maintain effective lubrication across such ranges, multigrade oils employ viscosity modifiers that keep performance consistent from < -20°C starts to above 120°C peaks.

The SAE 15W-our (!) grade, for example, flows readily in freezing conditions yet retains sufficient thickness under heat to support heavy-load cycling. Cold-weather operations demand specificity: studies by engine manufacturers show that oils below the recommended minimum viscosity cause 40% more starting friction, increasing wear on injectors and valvetrains. Conversely, high-temperature regimes call for oils engineered to resist viscosity drop—ensuring sludge formation remains minimal and clean oil circulation persists despite thermal stress.

This dual-variable challenge underscores why viscosity is not a static attribute but a dynamic function of the engine’s working environment. Maintaining accurate viscosity levels requires diligent monitoring and preventive care. Oil degrades over time due to oxidation, contamination, and additive depletion—all of which alter viscosity.

As enzymes and acids build in the crankcase, oil thickens or thins unpredictably, undermining its protective role. Fleet managers and maintenance teams enforce scheduled oil analysis using ASTM D7449 protocols to track viscosity trends and contamination thresholds. Routine sampling reveals early signs of degradation before components sustain damage.

Moreover, filtration and controlled storage conditions—avoiding excessive heat and moisture—preserve viscosity integrity longer. Research indicates that engines serviced with oil changed no later than manufacturer recommendations experience 30–40% fewer unplanned shutdowns due to wear-related faults. This level of maintenance is not optional but essential to sustain peak engine health.

Understanding viscosity grades and their performance implications demands technical awareness. Standard viscosity grades follow clear classifications: multi-grade oils (e.g., 10W-30) blend technologies that reduce viscosity at low temps while maintaining film strength at high operating temperatures. Single-grade oils like SAE 30 suit older or less dynamically stressed engines but often fall short under modern firing pressures and higher thermal loads.

Selecting the correct grade depends on engine specifications, fuel type, and operational demands. For heavy-duty trucks enduring mixed loads and long-haul cycles, engine manufacturers often recommend discretionary use of viscosity grades endorsed in technical documentation—never arbitrary substitutions. The precision in this choice directly influences efficiency, emissions compliance, and long-term reliability.

As heavy machinery and transportation networks rely on cleaner, faster, and more durable engines, mapping oil viscosity to engine needs becomes non-negotiable. The science behind viscosity extends beyond viscosity numbers to lubricant chemistry and additive synergy. Modern diesel engine oils incorporate viscosity index improvers (VI improvers), antioxidants, detergents, and anti-wear agents that stabilize viscosity through extreme conditions.

These additives work in tandem with base oils—either mineral or synthetic—to maintain consistent performance. Synthetic base oils, for instance, exhibit superior viscosity stability across temperatures, resisting breakdown better than petroleums. A comprehensive study by automotive lubricant researchers found that oils with enhanced VI improvers maintain 95% of target viscosity during thermal cycling, compared to under 70% for conventional formulations.

This chemistry ensures that critical lubrication properties endure even during extreme transient events—such as cold starts after idling or sudden load spikes—further preserving engine health. Practical application of viscosity knowledge empowers better maintenance decisions. Operators and technicians must interpret viscosity ratings not just from product labels but in context.

Engine manuals specify kinematic viscosity standards (e.g., 46 cSt at 40°C for ACEA A5/b soils), reflecting real-world operational demands. “Understanding viscosity means more than reading a viscosity number—it’s about matching oil behavior to what the engine experiences daily,” explains chief mec engineer Raj Patel. “For a city delivery van in winter, using an oil dynamically rated for low-temp flow prevents seized components; in a high-hp truck running hot, maintaining mid-range viscosity prevents blow-by and expands component life.” Real-world failure data shows that early, informed viscosity management reduces component replacement costs by up to 60% and extends drain intervals when using high-quality, grade-verified oils.

This proactive approach transforms routine maintenance into a strategic preservation tool. Viscosity standards continue evolving with engine technology and Euro Stage/Vempt P fuel regulations. As global emissions norms tighten and diesel powertrains face stricter cleanliness and efficiency targets, viscosity specifications are adapting.

Modern engines demand oils that support lower friction coefficients without sacrificing film strength, driving innovation in viscosity modifier chemistry and additive packages. The European lubricant directive, for instance, now requires oils to maintain viscosity stability for up to 20,000 hours under extreme cyclic load—mirroring real-world operating patterns. OEMs increasingly specify synthetic blends with tighter tolerance bands to match high-precision tolerances in fuel injection systems, turb

Related Post

What Channel Is The Yankee Game On Today? Find Out the Live Broadcast Game Streaming in Instant Clarity

Siem Reap International Airport: The Gateway to Angkor’s Timeless Miracles

Unlock the Hidden Potential of IPS Files: How to Open Them on iPhone in Minutes