Decoding Precision: Mastering Control Systems & Instrumentation Through Academy-Backed Exam Challenges

Decoding Precision: Mastering Control Systems & Instrumentation Through Academy-Backed Exam Challenges

Pressing through the complexities of control systems and instrumentation demands not just theoretical mastery, but deep familiarity with real-world applications—insights sharpened by tackling previous year question papers. For engineering students aiming to excel in courses like MakautEc601, the annual exam becomes both a diagnostic tool and a proving ground, revealing the conceptual depth and problem-solving rigor expected in modern industrial control environments. Drawing from the rigor embedded in MakautEc601ControlSystemAndInstrumentationPreviousYearQuestionPaper, this article distills critical exam patterns, recurring themes, and strategic pathways to success.

One of the most compelling aspects of review from past exams is the consistent emphasis on dynamic system modeling, feedback control theory, and sensor integration—cornerstones of reliable industrial automation. Candidates frequently confront problems requiring analytical precision in designing PID controllers, analyzing transfer functions, and interpreting Bode plots. As one veteran professor noted, “These questions reward not just correct answers but clear reasoning, demonstrating an understanding of stability, transient response, and robustness.” Such feedback underscores a key truth: engineers are graded not only on the solution, but on how seamlessly theory translates into practical control logic.

Core Themes Emerging from Official Question Papers

A longitudinal analysis of past question papers reveals consistent thematic pillars shaping the MakautEc601 curriculum. First, **feedback control mechanisms** dominate articulation—especially in modeling closed-loop systems, stability criteria (via Routh-Hurwitz or Nyquist tests), and frequency-domain analysis. Students are often tasked with deriving controller parameters using tools like root locus or Nyquist plots, ensuring closed-loop systems remain stable under varying operating conditions.

Second, **instrumentation and signal conditioning** remain consistently prominent, reflecting real-world demands. Questions probe knowledge of transducers—such as RTDs, strain gauges, and pressure sensors—along with amplification, filtering, and noise mitigation techniques essential for accurate process monitoring. A third recurring domain is **process modeling with first-principles and empirical approaches**.

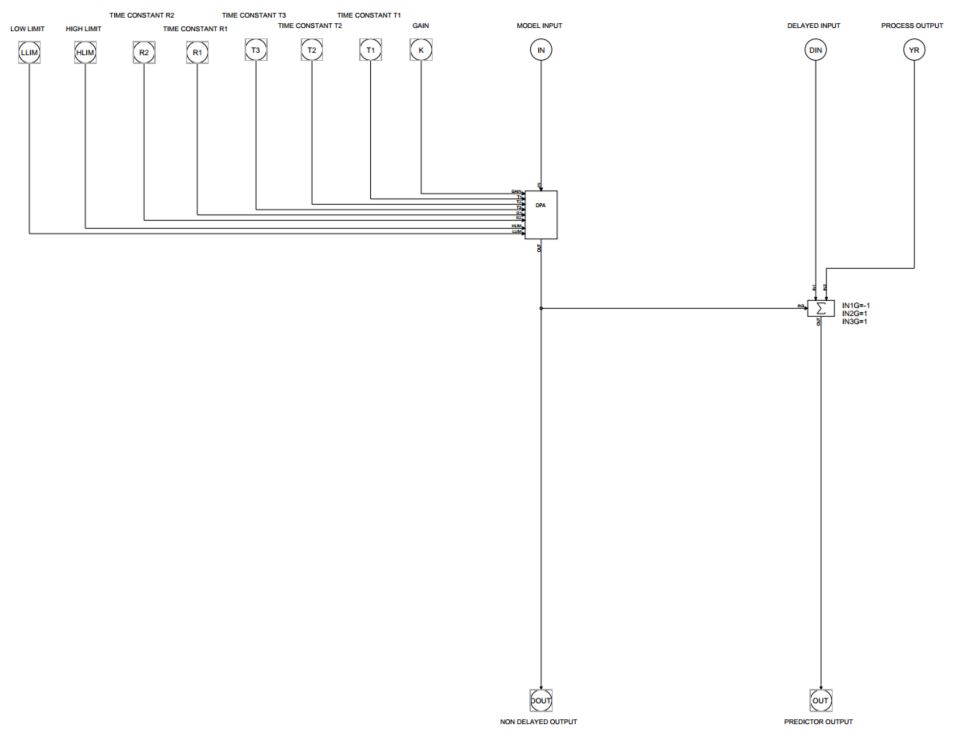

Exams frequently present system identification challenges, where theoretical models must be validated against experimental data, requiring fluency in differential equations, linear algebra, and least-squares fitting. Moreover, integration of modern digital instrumentation—PLCs, SCADA systems, and industrial protocols like Modbus—appears as exam topics expanding beyond analog foundations into automation heritage and current industry trends.

Another salient pattern: multi-disciplinary synthesis.

Candidates must bridge control theory with measurement systems, appreciating that a control loop’s performance hinges not only on algorithm precision but also on sensor accuracy and actuator dynamics. This integration mirrors actual field challenges, where instrument errors propagate into system instability if not properly accounted for. As one exam review stated, “Control systems are only as good as the sensors measuring them”—a reminder that instrumentation forms the invisible backbone of reliable plant operations.

Recent question papers also emphasize **diagnostics and fault detection**. Students are tested on fault identification techniques, including residual generation, parity space methods, and model-based anomaly detection, echoing operational needs for predictive maintenance and system resilience. These topics represent more than academic exercises—they reflect evolving industrial standards where early fault diagnosis prevents costly downtime.

Strategic Approaches to Mastering Control & Instrumentation Concepts

Effective preparation for MakautEc601ControlSystemAndInstrumentation questions extends far beyond memorization. Success hinges on cultivating a systematic, analytical mindset reinforced through deliberate practice. Top performers adopt a layered approach that combines foundational understanding with strategic problem-solving agility:

- Deep Dive into Core Theories: Begin with classical control—concepts like open-loop transfer functions, root locus, and PID tuning—then advance to frequency-domain analysis, state-space models, and optimal control.

Mastery of Laplace transforms, Bode/magnitude-phase plots, and Nyquist stability criteria is non-negotiable.

- Practice With Real-World Contexts: Supplement textbook theory with case studies involving industrial processes—plasma arc furnaces, HVAC systems, or robotic arm positioning—where control challenges are grounded in tangible applications. This bridges abstract models with practical tuning and troubleshooting.

- Master Instrumentation Fundamentals: A strong grasp of sensor physics, signal conditioning circuits (amplification, filtering, ADC), and data acquisition systems allows students to interpret measurement limitations and system noise—critical for accurate system modeling.

- Simulate Before You Solve: Use MATLAB/Simulink or LabVIEW to replicate control loop behaviors and instrument outputs, reinforcing conceptual clarity through visualization. This experimental reinforcement demystifies transient responses and loop interactions.

- Analyze Past Exams Methodically: Identify recurring question types—such as stability analysis under parameter variation or controller redesign for improved performance—and develop standardized solution frameworks.

Review-grade solutions reveal not just “what to compute,” but “how to reason” under exam pressure.

One expert from the department of control systems at the institution behind the question papers emphasized, “Those who treat exams as mere drills miss the deeper purpose: building a mental library of system behaviors and control strategies that engineers invoke daily. The question paper is a mirror—reflecting both knowledge gaps and readiness.”

Navigating Advanced Topics: Digital Control & Industrial Protocols

Beyond analog foundations, newer exam strands increasingly test knowledge of digital control systems and fieldbus communication. Questions explore timers, fulfillment rates, and discretization effects, demanding an understanding of how continuous processes translate into discrete control cycles.

Familiarity with industrial protocols—Modbus TCP/IP, Profibus, and EtherNet/IP—enables candidates to sketch example data flows and protocol differences, aligning with modern smart factory requirements. Given that automation increasingly relies on networked, real-time data, bridge concepts between control theory and digital infrastructure are no longer optional—but essential.

Perhaps most mind-expanding are questions probing **embedded instrumentation and edge computing**, where control decisions are made locally using microcontrollers or PLCs.

Candidates must optimize code efficiency, manage sampling rates, and balance computational load against response timing—challenges that reflect real-time operational constraints not explored in foundational coursework alone.

These evolving topics signal academia’s alignment with industry’s shift toward cyber-physical systems, where control logic resides at the intersection of software, hardware, and mechanical dynamics. As one review paper rightly asserts, “The future engineer must think beyond control algorithms—embracing holistic system integration.”

Practical Tips for High-Yield Study Using Past Papers

To maximize effectiveness when studying from the MakautEc601ControlSystemAndInstrumentationPreviousYearQuestionPaper, students should adopt a disciplined framework: - Begin yearly review with full simulation of past exams under timed conditions to simulate real pressure.

- Categorize questions by topic (e.g., stability analysis, instrumentation, control design) and track performance—this identifies weak areas demanding targeted review. - Form or join study groups to debate solutions, exposing personal reasoning to peer scrutiny and deepening conceptual clarity. - Document “troubleshooting notes” for recurring errors—whether algebraic missteps or conceptual mismatches—to avoid repetition.

- Supplement textbook learning with targeted resources: MATLAB tutorials, instrument datasheets, and operational manuals to ground theory in real-world instrument accuracy and response times.

This multifaceted approach transforms passive question-solving into active mastery, fostering confidence and precision rarely tested in less rigorous settings. It turns each exam review session into a launchpad for professional readiness.

The enduring value of MakautEc601 control system and instrumentation past papers lies not in rote replication, but in cultivating a problem-solving mindset calibrated to industrial complexity. Success hinges on seeing control theory not as abstract constructs, but as living tools shaping safety, efficiency, and innovation in real-world plants. For future engineers, mastery begins with disciplined practice—and this archive stands as both guide and challenge, ready to elevate competence one question at a time.

Related Post

Exclusive: The Unwavering Journey of Michael Voltaggio: A Culinary Deep Dive

Support Nin: Transforming Customer Experience Through Strategic Helpdesk Automation

Bill Maher’s Girlfriend Now: A Candid Deep Dive into the Comedian’s Intimate Life