Crush Logistics Costs: How the Least Cost Method Optimizes Transportation Efficiency

Crush Logistics Costs: How the Least Cost Method Optimizes Transportation Efficiency

In an era where supply chains demand precision and cost containment, the Least Cost Method emerges as a decisive tool for optimizing transportation networks. Used across industries from retail to manufacturing, this analytical approach minimizes movement expenses while ensuring timely delivery—balancing speed, reliability, and financial prudence. As global supply chains face rising fuel prices, congestion, and environmental scrutiny, adopting the Least Cost Method isn’t just strategic—it’s essential for sustainable competitiveness.

The Least Cost Method is a systematic procedure used to determine the most economical way to transport goods between origins and destinations, factoring in multiple variables such as distance, mode of transport, capacity utilization, delivery time, and operational risk. By integrating data-driven decision-making with strategic planning, this method identifies routes and transportation modes that deliver maximum value with minimal expenditure.

At its core, the method evaluates transportation alternatives across a multidimensional cost matrix.

Diehl Transportation, a leader in supply chain solutions, explains: “The Least Cost Method goes beyond simple route selection. It balances cost efficiency with service performance, ensuring logistics plans align with broader business goals.” This holistic evaluation considers not just the per-mile fare, but also inventory holding costs, fuel variability, loading/unloading times, and potential bottlenecks that could disrupt flow.

One of the method’s most impactful strengths lies in its ability to optimize mode selection.

Transportation modes—road, rail, air, and intermodal—each carry distinct cost structures and speed profiles. For example, while air freight offers rapid delivery, its high costs and carbon footprint make it unsuitable for non-urgent shipments. Conversely, freight rail often provides a cost-effective middle ground for bulk freight, especially over long distances.

The Least Cost Method systematically weighs these trade-offs, matching each shipment’s urgency and volume to the most economical yet efficient transport option.

- Road transport excels in flexibility and last-mile delivery, ideal for short- to medium-haul routes.

- Rail reduces long-haul expenses and emissions but requires proper intermodal integration.

- Intermodal logistics combine rail and truck transport, optimizing cost-efficiency without sacrificing reliability.

- Air freight supports high-value, time-sensitive cargo despite premium pricing.

Equally critical is network design. The Least Cost Method doesn’t treat routes as isolated segments but as interconnected nodes within a larger logistics web. Optimal hub placement, consolidation points, and transshipment hubs can drastically reduce redundant movement and idle time.

A publicly shared example illustrates this: a major consumer goods distributor reduced national transportation costs by 18% after restructuring its regional hubs, using the Least Cost Method to analyze shipment densities, transfer delays, and carrier contract efficiencies.

- Centralized hubs consolidate freight, boosting truckload utilization.

- Strategic routing reduces backhauls and empty miles—key waste in freight operations.

- Dynamic routing adjusts in real-time to traffic, weather, or disruptions, maintaining cost efficiency under uncertainty.

Technology amplifies the Least Cost Method’s impact. Real-time data from GPS, traffic monitoring systems, freight marketplaces, and predictive analytics feeds into optimization algorithms, enabling precise, forward-looking decisions. Advanced Transportation Management Systems (TMS) now integrate machine learning to forecast cost trends and automate mode selection based on current market conditions.

This shift from static planning to adaptive logistics ensures that cost savings are not just theoretical but executed dynamically.

Data integration and visibility

modern platforms link carrier performance, weather forecasts, fuel price trends, and customs delays into a single analytical layer. “The power lies in data coherence,” says logistics analyst Mark Tran. “When every variable is modeled—whether seasonal demand spikes or port congestion—the Least Cost Method becomes far more than a cost calculator; it transforms into a strategic orchestrator of flow.”Environmental considerations further elevate the method’s relevance.

Companies increasingly face pressure to reduce carbon footprints, and the Least Cost Method supports dual objectives: cutting expenses while improving sustainability. By favoring fuel-efficient modes, minimizing empty runs, and consolidating shipments, businesses simultaneously lower costs and emissions. Diesel savings from optimized load factors combined with electrified last-mile fleets exemplify this synergy.

As sustainability goals tighten, the Least Cost Method evolves from a tactical tool into a core enabler of green logistics.

Environmental and operational synergy

- Fuel savings from optimized routing directly reduce greenhouse gas emissions.

- Higher load factors maximize asset utilization, making each mile “greener per unit.”

- Integration with carbon tracking systems enhances corporate ESG reporting accuracy.

Practical application demands structured execution. Industry leaders recommend five key steps: 1. Define shipment profiles—urgency, volume, destination, and service requirements.

2. Map carrier capabilities, contract rates, and historical performance. 3.

Input all cost components—fuel, labor, tolls, transit time penalties, and compliance. 4. Use optimization software to generate ranked alternatives—balancing cost, time, and risk.

5. Monitor, analyze, and refine continuously using real-time performance data.

Every implementation reveals opportunities: case studies show carriers saving 15–25% annually by adopting method-based routing, while manufacturers cut inventory carrying costs by aligning delivery schedules with production cycles. The Least Cost Method is not a one-off fix but a discipline that matures with data maturity.

As global commerce grows more complex, effective transportation optimization remains a persistent challenge. The Least Cost Method stands out as the most robust framework for navigating this complexity—merging financial logic with operational agility. It empowers organizations to move beyond reactive shipping, enabling proactive, intelligent decisions that keep logistics lean, responsive, and sustainable.

In an age where margins are razor-thin and competition relentless, mastering this method isn’t optional—it’s foundational. By embedding cost-efficiency into the DNA of transportation planning, businesses unlock not just savings, but long-term resilience. The future of logistics belongs to those who see optimization not as a task, but as a strategy—one where every mile counts, every cost is intentional, and every shipment is a step toward superior performance.

Related Post

Did Layne Staley Have Children? The Private Family Life of a Heavy Metal Legend

Live Badminton Matches Today: Malaysia Match Times Revealed

Stephen Hawking and Epstein Island: A Crawl Through Scientific Triumph and Moral Shadow

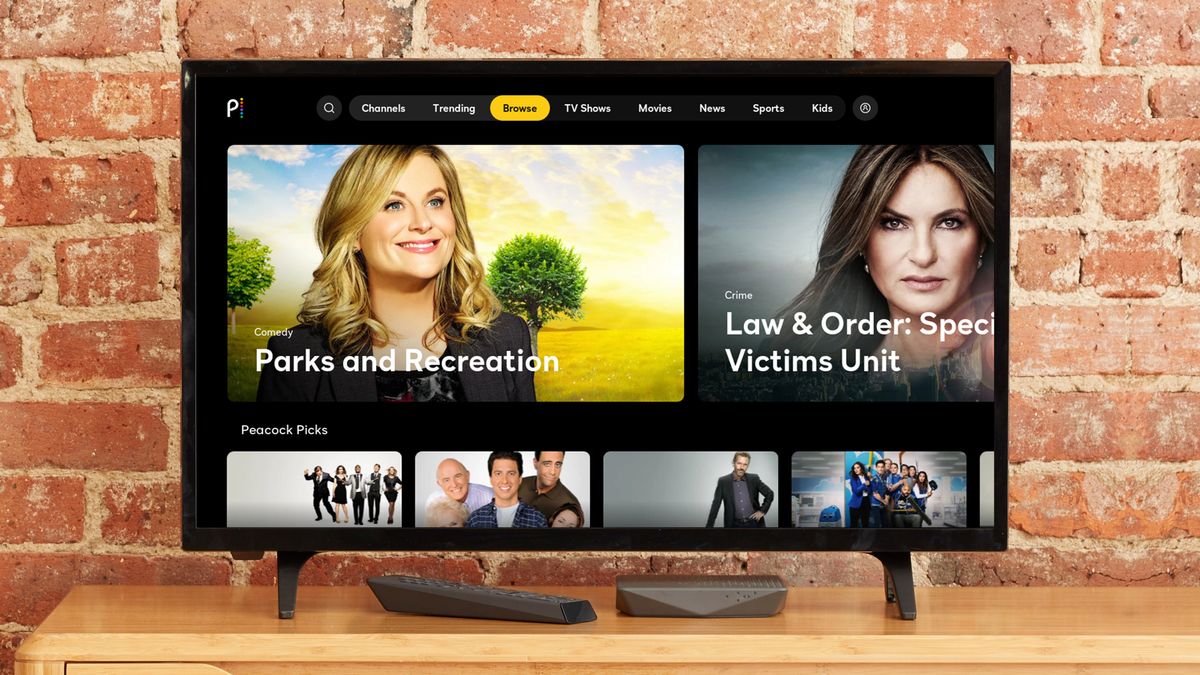

Watch Peacock TV on Linux: The Simple Guide to Streaming America’s Premier Streaming Service