Bundle Rooski: The Swiss Precision Powerhouse Redefining Industrial Performance

Bundle Rooski: The Swiss Precision Powerhouse Redefining Industrial Performance

In a world where reliability and engineering excellence set market differentiators, Bundle Rooski stands out as a quietly dominant force in industrial automation and precision components. Specializing in high-tolerance electrical and mechanical assemblies, the company has become synonymous with durability, performance, and innovation—qualities embodied in its flagship product suite: Bundle Rooski. From industrial control systems to power distribution units, this line delivers not just components, but systems engineered for longevity in demanding environments.

Origins and Evolution: From Local Workshop to Global Standard Founded in the early 2000s in Switzerland, Bundle Rooski began as a small precision workshop focused on custom electrical connectors and mounting solutions. What started as localized craftsmanship quickly evolved into a benchmark for performance-driven design. Over two decades, the company has grown exponentially, now exporting to over 30 countries and supplying major manufacturers in automation, renewable energy, and industrial machinery.

Internal leadership emphasizes that “we don’t chase trends—we build the foundation beneath them,” a philosophy that continues to guide product development. This long-term vision is evident in each generation of Bundle Rooski products, which integrate decades of mechanical insight and cutting-edge material science.

Precision Engineering: The Core of Bundle Rooski’s Identity

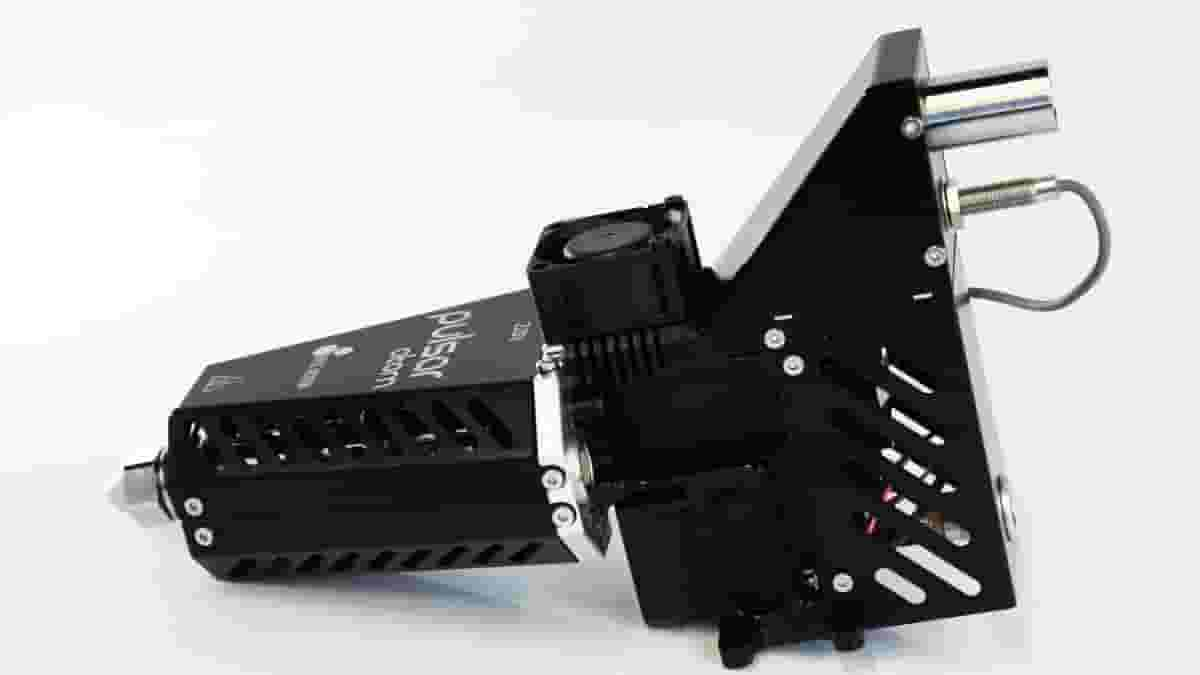

At Bundle Rooski, precision isn’t a marketing claim—it’s a measurable standard.Every component is manufactured under strict tolerances, with tightest specifications often below 0.01 mm, ensuring flawless integration in complex systems. - **Tolerance Control:** Every stud, terminal, and housing is precision-machined using CNC systems calibrated to industry’s most demanding benchmarks. - **Material Science:** Advanced alloys and composites resist corrosion, extreme heat, and vibration—critical for applications in manufacturing plants and outdoor installations.

- **Quality Assurance:** Rigorous automated and manual inspections follow each production batch, employing AI-driven vision systems to detect microscopic defects before delivery. Industry analysts note that “Bundle Rooski’s commitment to precision creates a ripple effect: systems built on their components experience 30–50% longer lifecycle and fewer field failures,” reinforcing their reputation as a reliability anchor.

Innovation in Action: Cutting-Edge Solutions Tailored to Modern Needs

While rooted in precision, Bundle Rooski is far from a legacy brand.The company invests heavily in R&D, focusing on next-generation technologies that meet evolving industrial demands. - **Smart Integration:** Modular designs now include embedded sensors and IoT-ready interfaces, enabling real-time monitoring and predictive maintenance in Industry 4.0 environments. - **Energy Efficiency:** New lineups feature low-loss connectors that minimize energy dissipation, supporting sustainability goals in power distribution networks.

- **Customization at Scale:** Leveraging digital twin modeling, engineers collaborate with clients to tailor solutions precisely—whether adjusting thermal profiles or optimizing mechanical fit. One breakthrough product exemplifies this forward path: the RooskiDesk 9000, a hybrid power distribution unit combining modular scalability with AI-driven load balancing, now deployed in smart factories worldwide.

End-to-End Support: From Concept to Commissioning

What separates Bundle Rooski from its peers isn’t just product excellence, but a holistic support framework built around collaboration.Technical service engineers work closely with clients from design through deployment, providing consultations on integration, environmental resilience, and lifecycle management. - **Custom Documentation:** Detailed MEP (Mechanical, Electrical, Plumbing) profiles, CAD models, and BOMs (Bill of Materials) ensure seamless project handoffs. - **Field Technical Teams:** On-site support during installation ensures optimal performance and rapid troubleshooting.

- **Training & Knowledge Transfer:** Workshops and digital resources empower users to maximize system efficiency and maintenance uptime. Quoted company lead engineer Markus Weber stated: “We see ourselves as partners in our customers’ success, not just suppliers—this mindset ensures innovation translates directly into operational gains.”

Economic and Market Performance: A Track Record of Reliable Growth

Despite economic headwinds, Bundle Rooski has demonstrated consistent double-digit growth, with revenues rising from €18 million in 2015 to over €58 million in 2024. This upward trajectory stems from expanding market segmentation and strategic partnerships with key players in automation, clean tech, and heavy industry.Looking at regional performance, Western Europe remains the largest market

Related Post

Eva Marie Reveals Vince McMahons Input With Her WWE Presentation

IoS: The Lifesaving Intelligence Operating at the Core of Modern Medicine

Does Harry Potter Die or Will Death Ever Leave the Boy Who Defied Fate?

Time In La: Mastering the Art of Temporal Precision in Modern Communication