Agptek: From Humble Beginnings to Tech Titun — The Rise of a Disruptive Innovator

Agptek: From Humble Beginnings to Tech Titun — The Rise of a Disruptive Innovator

In a world where tech brands rise and fall with astonishing speed, Agptek stands out as a masterclass in resilience, innovation, and vision. Born from a quiet startup nestled in China’s evolving electronics landscape, Agptek has ascended to become a global force in industrial automation, AI-driven manufacturing solutions, and smart hardware ecosystems. With products trusted by enterprises across continents and a reputation for merging precision engineering with forward-thinking software, Agptek’s journey reflects both the opportunities and expectations shaping today’s high-tech sector.

Founded in the early 2010s, Agptek emerged during a transformative period for China’s tech industry, when innovation hubs began attracting domestic talent and investment at an unprecedented scale. The company’s origins are rooted in a small team of electrical engineers and software developers who shared a singular mission: to bridge the gap between traditional industrial machinery and the intelligent, connected systems modern manufacturing demanded. “Agptek was never about chasing trends,” says Li Wei, co-founder and current Chief Technology Officer.

“Our roots are in building real tools that solve tangible problems on the factory floor — not flashy gadgets, but reliable, scalable technology designed to integrate seamlessly into existing workflows.”

From day one, Agptek prioritized deep technical expertise over rapid expansion. The founding team leveraged hands-on experience in embedded systems and sensor integration, founding the company in a repurposed R&D facility in Shenzhen — a city synonymous with hardware innovation. This early decision to anchor operations in Shenzhen’s manufacturing ecosystem proved pivotal, enabling Agptek to rapidly prototype, test, and deploy solutions tailored to real industrial environments.

From Prototype to Global Reach: The Evolution of Agptek’s Product Portfolio

Agptek’s product journey began with niche industrial sensors and data acquisition modules — critical components for monitoring production lines. Yet it was not blinking lights or gimmicks that defined its breakthrough: the company’s early mastery of edge computing and low-latency data processing laid the groundwork for its defining strength — intelligent, real-time decision-making at scale.By 2016, Agptek introduced its signature Industrial IoT (IIoT) gateway, a device engineered to aggregate, analyze, and transmit machine data with unprecedented efficiency.

Unlike generic off-the-shelf solutions, Agptek’s gateway was optimized for harsh industrial environments — dusty, noisy, and power-constrained factories — ensuring uptime and reliability where it mattered most.

Key milestones illustrate Agptek’s rapid ascent: - 2017: Launch of Agptek EdgeOS, a proprietary operating system tailored for industrial edge devices, reducing latency by 40% while boosting cybersecurity defenses. - 2019: Entry into the European market with fully compliant SCADA-compliant automation modules, signaling Agptek’s shift from regional player to global contender.

- 2021: Release of AI-enhanced predictive maintenance platforms, combining machine learning with sensor analytics to anticipate equipment failures with up to 92% accuracy. - 2023: Strategic partnership with Siemens and Rockwell Automation, integrating Agptek’s edge intelligence into leading industrial control systems. Each step marked a deliberate effort to address a core industrial pain point: the gap between raw data and actionable insight.

Agptek’s devices don’t just collect — they interpret. That capability, combined with modular design and interoperability, made them indispensable across sectors ranging from automotive manufacturing to pharmaceutical packaging.

Engineering Excellence: The Agptek Advantage in Design and Technology

At Agptek’s core is a philosophy defined by engineering rigor and practical ingenuity.The company invests heavily in in-house R&D, with dedicated labs in Shenzhen and Shanghai focused on hardware-software co-design. This vertically integrated model allows Agptek to bypass common industry bottlenecks — such as vendor lock-in, outdated firmware, or one-size-fits-all architectures.

Engineers at Agptek emphasize ruggedness, security, and scalability at every stage.

“We don’t treat security as an afterthought,” explains Zhang Ming, Head of Product Architecture. “Every firmware update undergoes penetration testing, and cryptographic modules are hardwired into base designs — not bolted on.” This approach has fortified Agptek’s reputation among industrial clients deeply concerned with operational continuity and regulatory compliance.

The technological foundation of Agptek’s most influential products reveals further depth.

The Agptek EdgeIQ processor, for example, integrates AI inference accelerators and real-time data compression algorithms that reduce bandwidth needs by 60% without sacrificing accuracy. Deployed across distributed factory networks, this chip enables faster local processing, minimizes cloud dependency, and strengthens data sovereignty — a critical factor in regions with strict privacy laws like the EU’s GDPR.

Another hallmark is Agptek’s commitment to open standards.

Unlike proprietary systems that entrench customers in single vendors, Agptek products adhere to OPC UA, Modbus, and MQTT protocols, ensuring seamless integration with legacy machinery and third-party software. This interoperability has been a key driver of client adoption, particularly among SMEs seeking to modernize without massive infrastructure overhauls.

Market Position and Industry Impact: Agptek Rewriting the Automation Playbook

While Agptek operates largely behind the scenes, its influence is everywhere in the evolving factory floor.The company has positioned itself as a bridge between legacy manufacturing practices and the emerging era of Industry 4.0 — a term often bandied about but rarely mastered. Agptek’s customer base spans Fortune 500 manufacturers, agribusinesses, and energy firms, all deploying Agptek systems to gain operational precision, reduce downtime, and unlock new revenue streams through data-driven optimization.

Quantifying Agptek’s impact is challenging, but telling indicators include: - Over 8,000 active installations in 45 countries, with annual revenue growth averaging 35% from 2020 to 2023.

- Awards such as “Top Industrial Automation Innovator” by Quarantine Intelligence (2022) and recognition in Forbes Global 2000 Tech List. - Strategic expansions into North America and Southeast Asia, with regional hubs in Austin, Dubai, and Singapore enabling faster service and localized support.

Perhaps most notably, Agptek has played a constructive role in advancing sustainability within manufacturing.

Its energy-aware control algorithms reduce power consumption by an average of 28% across tracked lines, while predictive maintenance cuts unplanned downtime and material waste. These outcomes align with global decarbonization goals, placing Agptek not just as a tech supplier but as a partner in responsible industrial evolution.

The Human Touch Behind the Machines

Beyond circuits and code, Agptek’s success is driven by people — a team steeped in technical rigor and passionate about solving real-world challenges.Founders Li Wei and Zhang Ming frequently emphasize a culture of “deep collaboration” between engineers, field technicians, and end users. This grassroots approach ensures that each product iteration reflects frontline realities rather than abstract market trends.

Internal initiatives reinforce this ethos.

Each quarter, Agptek engineers participate in “field immersion days,” spending days on factory floors observing workflows, collecting user feedback, and refining prototypes firsthand. “We’re not building for customers — we’re building with them,” says Li. “That’s how you design for usability, reliability, and lasting impact.”

Mentorship and talent development are equally prioritized.

The company sponsors university-level robotics programs and hosts annual hackathons, fostering the next generation of industrial technologists. This investment ensures Agptek remains agile, turning fresh talent into future innovators.

Looking Ahead: Agptek’s Vision for the Next Industrial Frontier

As artificial intelligence, 5G, and digital twins reshape industrial landscapes, Agptek continues to evolve — targeting labs, smart cities, and autonomous systems with ever-smarter edge solutions.The company is already prototyping AI co-processors designed to run complex generative models directly on factory machinery, enabling on-site design optimization and real-time process tuning.

“Agptek’s mission remains unchanged: to make intelligence accessible to every factory, regardless of size or location,” says CEO Wang Jun in a recent industry forum. “We’re not just building technology — we’re building a smarter, more resilient manufacturing world.”

With sustained R&D investment, strategic global partnerships, and a laser focus on solving operational pain points, Agptek has solidified its place as more than a regional brand.

It is, increasingly, a global architect of the next industrial revolution — where edge devices think, adapt, and deliver measurable value at scale. In an era where disruption is constant, Agptek’s journey stands as a compelling example of how technical depth, customer centricity, and relentless innovation converge to define a true tech pioneer.

Related Post

The Foundation of Geometric Success: Unlocking All Things Algebra’s Geometry Basics Answer Key

When Language Fools the Mind: Spotting Spurious Definitions in Everyday Speech

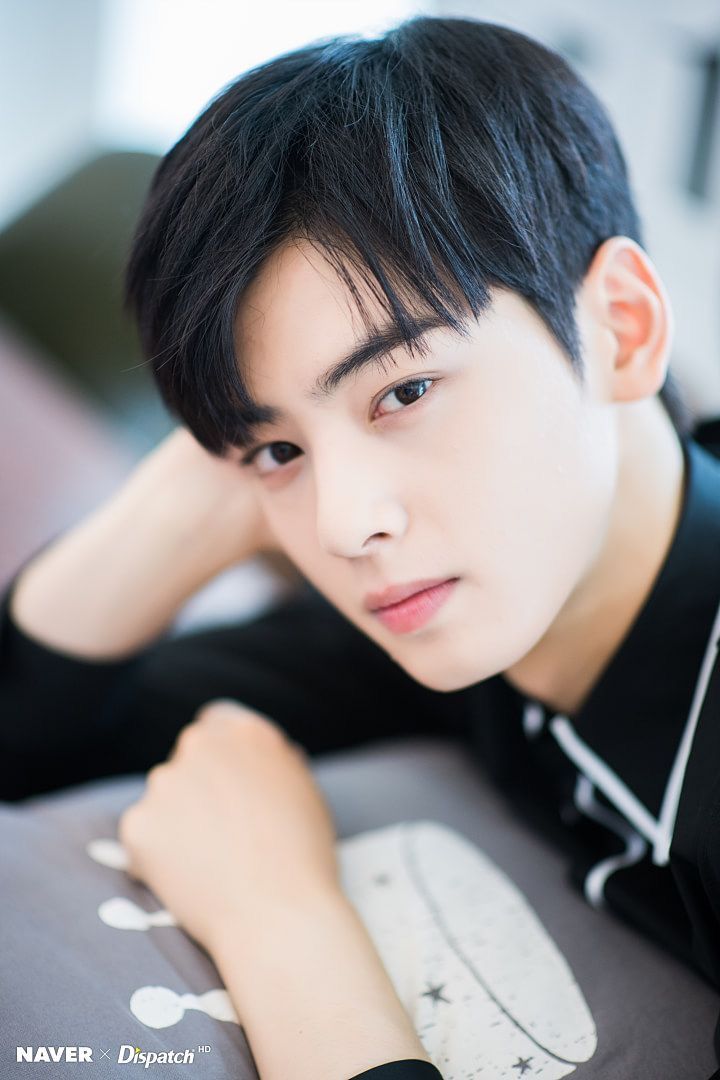

Reveal The Hidden Truth: Cha Eun Woo’s Authentic Family Frozen in Photographs