45 Millimeters to Inches: The Precision Conversion That Shapes Global Standards

45 Millimeters to Inches: The Precision Conversion That Shapes Global Standards

Each millimeter carries precise weight—often measured in millimeters, but equally critical when translated to inches. The conversion of 45 millimeters to inches is far more than a numbers game; it’s a foundational reference point in engineering, manufacturing, healthcare, and countless global industries. At exactly 45 mm, this value sits at a pivotal intersection: just shy of one-third of an inch, yet crucial for specifications requiring high accuracy.

When measured in 45 mm to inches, the result converges at 1.77155 inches—less than a fraction beyond the widely adopted .75-inch standard, yet indispensable for calibrated measurements.

Understanding millimeter-to-inch conversions is vital across sectors where tolerances define success. A 45 mm component may seem diminutive, yet in precision-focused fields, even a tenth of a millimeter alters performance.

“Accuracy in measurement isn’t just about numbers—it’s about reliability,” explains Dr. Elena Marquez, senior metrologist at the International Standards Organization (ISO). “When engineers work at micron levels, converting 45 mm to inches ensures consistency across borders and disciplines.”

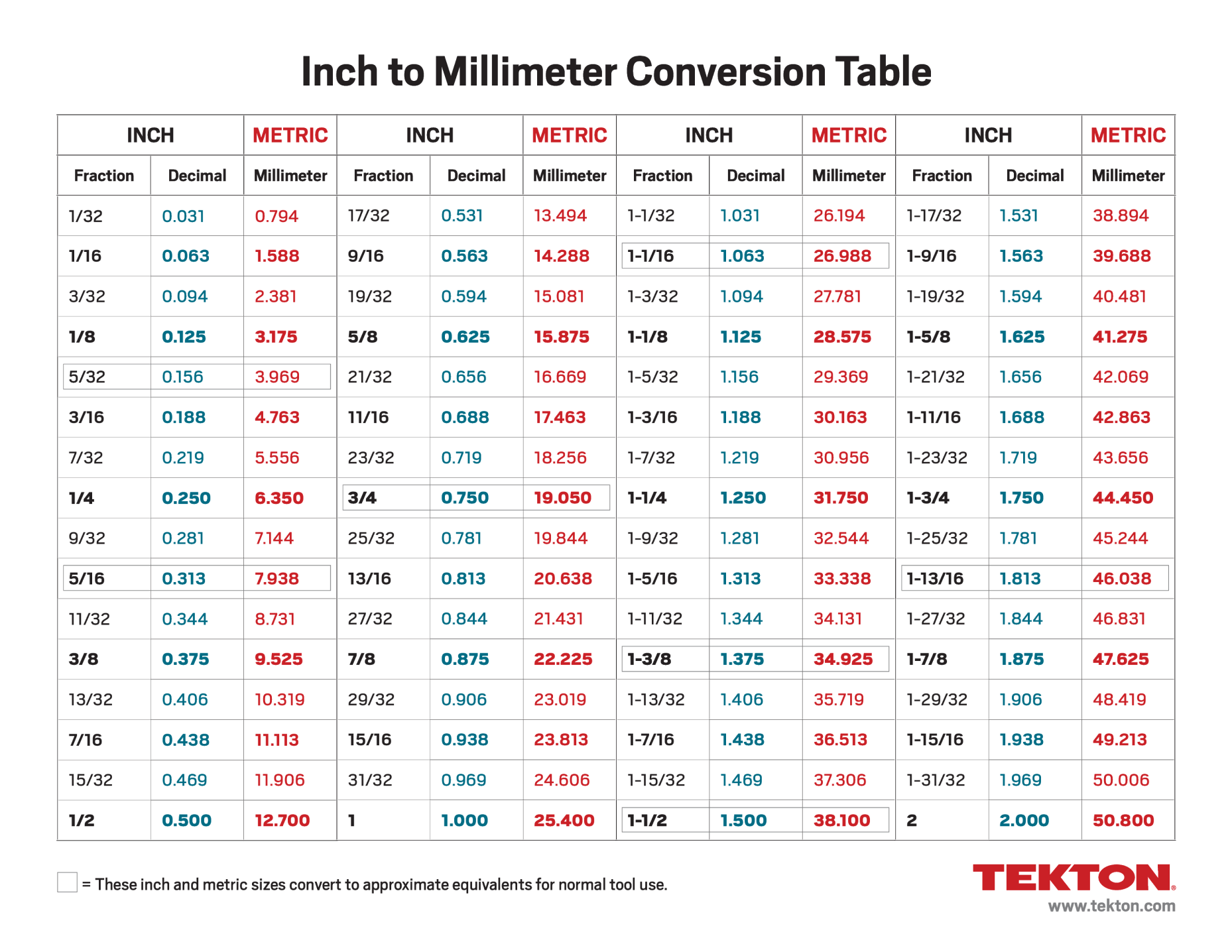

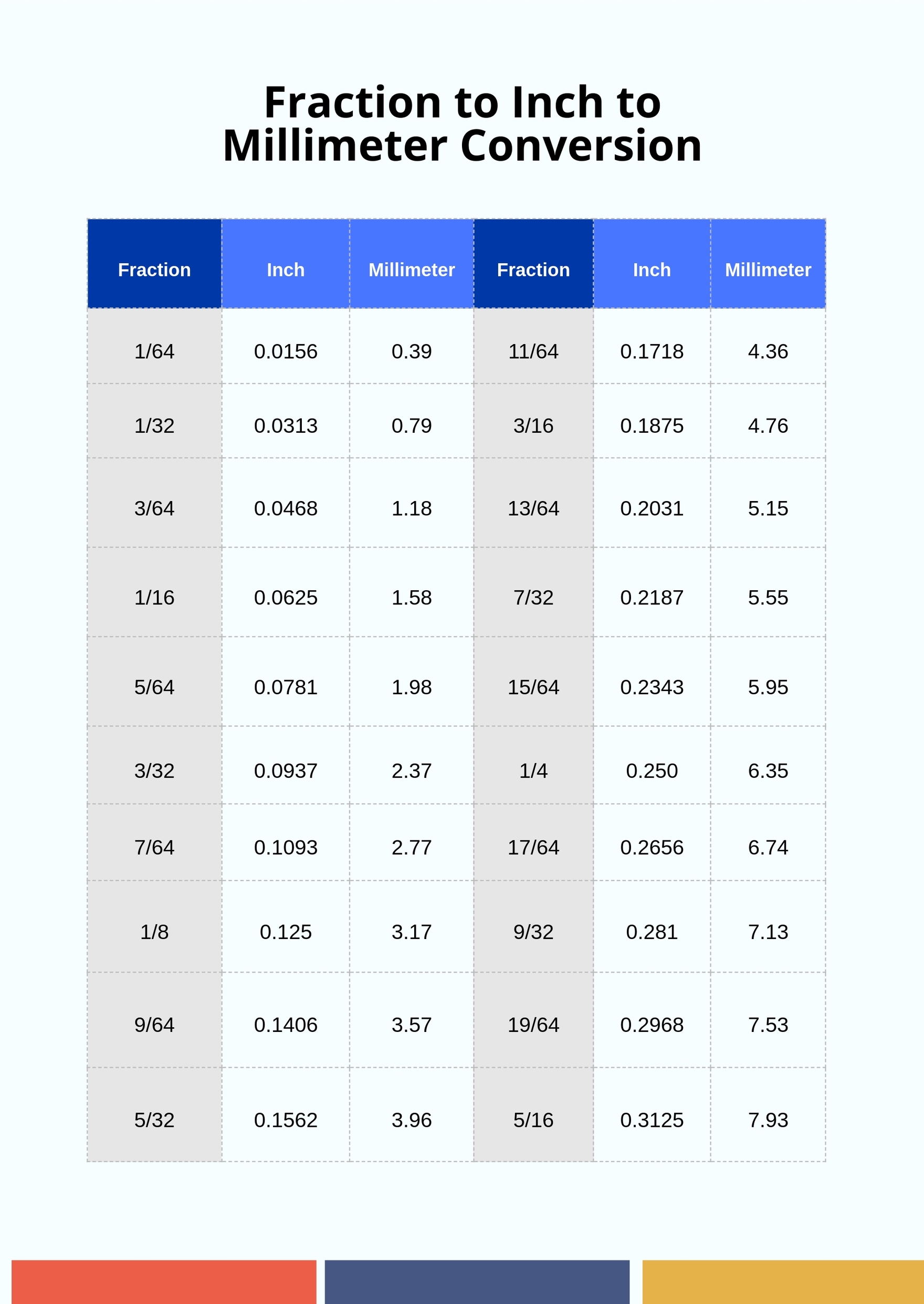

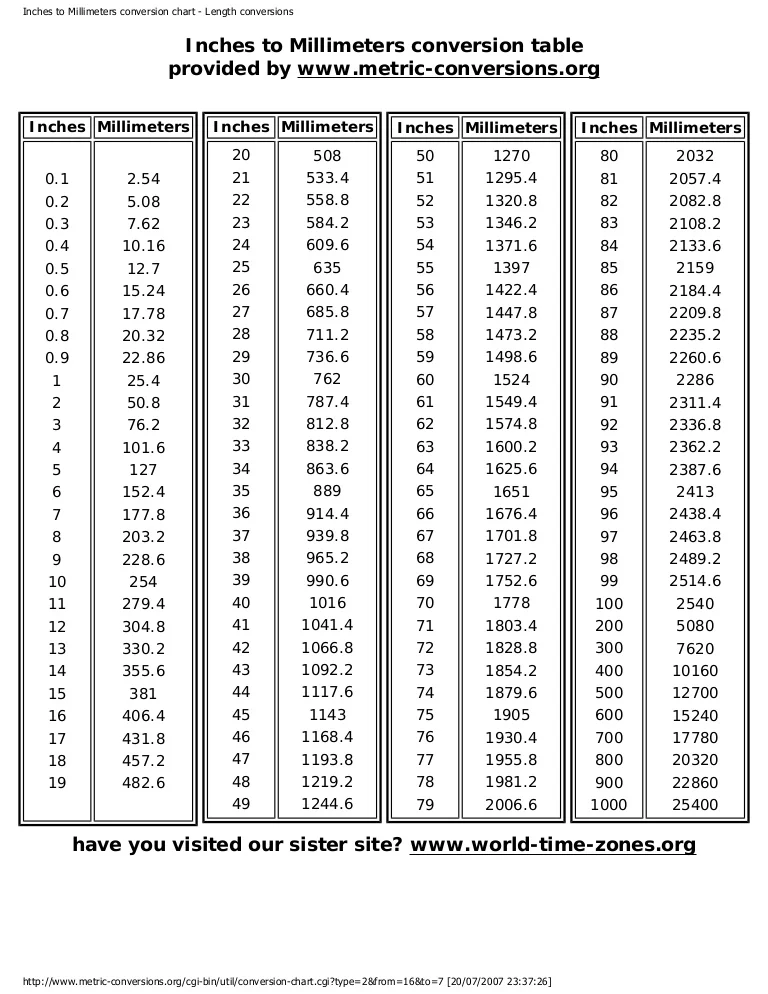

To unpack the conversion: 1 inch equals exactly 25.4 millimeters.

Dividing 45 mm by 25.4 delivers the precise equivalent: 1.77155 inches—a figure now embedded in technical documentation, CAD software, and international compliance codes. This conversion is not arbitrary: it forms the backbone of interoperability between metric and imperial systems, a necessity in global supply chains and multinational projects. Manufacturers in Japan, suppliers in Germany, and designers in the U.S.

all rely on this standard to ensure parts meet shared specifications without error.

Beyond theory, practical applications illuminate the necessity of exactness. Construction blueprints, aerospace schematics, and medical device manufacturing all reference this conversion.

Consider a surgical instrument requiring a 45 mm shaft: translating that to inches ensures seamless integration with imported implants or calibration tools from imperial-designed facilities. Another example: automotive components printed via precision 3D modeling depend on exact millimeter-to-inch ratios to guarantee switch-in fit without reworking. When specifications demand tight tolerances, 1.77155 inches guarantees parts align down to the finest detail.

Historically, the inertia of the imperial system persists in pockets of industry, especially in the United States, where everyday units dominate public life. Yet global standards increasingly anchor decisions to metric equivalents. The adoption of 45 mm to inches in technical guides, ISO certifications, and international trade agreements reflects a century-long shift toward universal measurement consistency.

This shift isn’t just convenient—it’s revolutionary for minimizing errors in an interconnected world.

Technology amplifies the relevance of precise conversion. Modern CAD software automatically translates 45 mm to 1.77155 inches with a click, enabling real-time cross-referencing and minimizing human miscalculation.

Quality control systems in manufacturing use millimeter-to-inch lookup tables to verify dimensional conformity before final assembly. Even everyday users encounter this conversion indirectly—measuring apps, smart rulers, and online conversion tools all serve a global rhythm of metric-imperial alignment, with 45 mm consistently yielding 1.77155 inches as the benchmark.

Despite the metric system’s scientific refinement, the inch remains a deeply ingrained unit in specific contexts.

Aviation, defense, and legacy manufacturing systems continue to reference inch-based dimensions. Converting 45 mm ensures these vintage and active standards stay compatible. In aerospace, for example, an 18.85 mm diameter bolt measured as 0.746 inches directly bridges old and new engineering philosophies.

Similarly, military equipment calibrated in U.S.-standard specs depends on this precise conversion to maintain deployability across allied forces using metric systems.

The transformation of 45 mm to inches—45 mm = 1.77155 inches—stands as a silent linchpin in modern technical language. It bridges continents, disciplines, and eras, ensuring that nothing from a micrometer plane shift to a centimeter-length tool functions out of sync.

In a world demanding unprecedented precision, such exact conversions underscore how small measurements shape large outcomes. As global collaboration deepens, this standard remains unshakable—proving that in the realm of accuracy, even an inch’s worth of clarity makes all the difference.

Ultimately, the journey from 45 millimeters to inches transcends mere arithmetic.

It represents the marriage of metric rigor and universal usability, a quiet yet indispensable force behind precision in the modern age. Whether calibrating a life-saving device or fitting interchangeable parts across borders, this conversion ensures foes become friends—units reconciled, industry unified, and excellence guaranteed.

Related Post

Mark Farese Age Wiki Net worth Bio Height Girlfriend

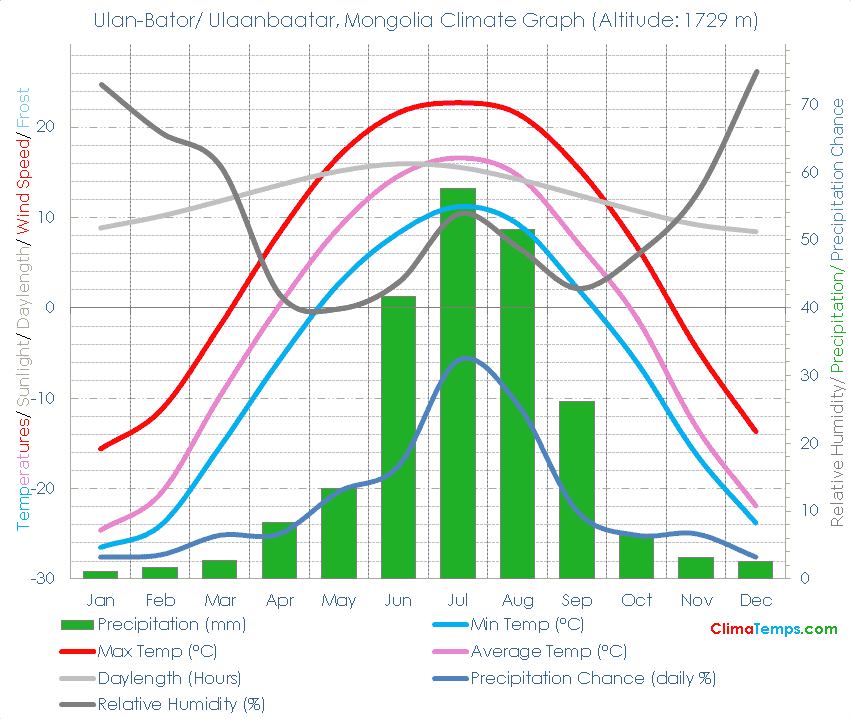

Ulaanbaatar, Mongolia: Decoding Current Temperatures and Climate Seasons

Don Jackson North: Architect of Modern North American Golf Innovation

Did You Know San Francisco Craigslist Could Shake Up Urban Housing with This Bold Experiment?